Product Description

Company Profile

Workshop

Detailed Photos

Product Description

| Material | Alloy Steel, Copper alloy(brass,silicon bronze,phosphor bronze,aluminum bronze,beryllium copper),Stainless Steel,Aluminum,Titanium, Magnesium, Superalloys,Molybdenum, Invar,,Zinc,Tungsten steel,incoloy,Nickel 200,Hastelloy, Inconel,Monel,ABS, PEEK,PTFE,PVC,Acetal. |

| Surface Treatment | Zn-plating, Ni-plating, Cr-plating, Tin-plating, copper-plating, the wreath oxygen resin spraying, the heat disposing, hot-dip galvanizing, black oxide coating, painting, powdering, color zinc-plated, blue black zinc-plated, rust preventive oil, titanium alloy galvanized, silver plating, plastic, electroplating, anodizing etc. |

| Producing Equipment | CNC machine,automatic lathe machine,CNC milling machine,lasering,tag grinding machine etc. |

| Drawing Format | Pro/E, Auto CAD, CZPT Works, UG, CAD/CAM, PDF |

| Managing Returned Goods | With quality problem or deviation from drawings |

| Warranty | Replacement at all our cost for rejected products |

| Main Markets | North America, South America, Eastern Europe , West Europe , North Europe, South Europe, Asia |

| How to order | * You send us drawing or sample |

| * We carry through project assessment | |

| * We make the sample and send it to you after you confirmed our design | |

| * You confirm the sample then place an order and pay us 30% deposit | |

| * We start producing | |

| * When the goods is done, you pay us the balance after you confirmed pictures or tracking numbers. | |

| * Trade is done, thank you!! |

Quality Control

Packaging & Shipping

Customer Reviews

FAQ

Q1:What kind of information do you need for quotation?

A: You can provide 2D/3D drawing or send your sample to our factory, then we can make according to your sample.

Q2: Can we CZPT NDA?

A: Sure. We can CZPT the NDA before got your drawings.

Q3: Do you provide sample?

A: Yes, we can provide you sample before mass order.

Q4: How can you ensure the quality?

A: We have profesional QC,IQC, OQC to guarantee the quality.

Q5: Delivery time?

A: For samples genearlly need 25 days. Mass production: around 30~45 days after receipt of deposit (Accurate delivery time

depends on specific items and quantities)

Q6: How about the transportation?

A: You can choose any mode of transportation you want, sea delivery, air delivery or door to door express.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Alloy Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | IT6-IT9 |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Real Axis |

| Customization: |

Available

| Customized Request |

|---|

How do drive shafts ensure efficient power transfer while maintaining balance?

Drive shafts employ various mechanisms to ensure efficient power transfer while maintaining balance. Efficient power transfer refers to the ability of the drive shaft to transmit rotational power from the source (such as an engine) to the driven components (such as wheels or machinery) with minimal energy loss. Balancing, on the other hand, involves minimizing vibrations and eliminating any uneven distribution of mass that can cause disturbances during operation. Here’s an explanation of how drive shafts achieve both efficient power transfer and balance:

1. Material Selection:

The material selection for drive shafts is crucial for maintaining balance and ensuring efficient power transfer. Drive shafts are commonly made from materials such as steel or aluminum alloys, chosen for their strength, stiffness, and durability. These materials have excellent dimensional stability and can withstand the torque loads encountered during operation. By using high-quality materials, drive shafts can minimize deformation, flexing, and imbalances that could compromise power transmission and generate vibrations.

2. Design Considerations:

The design of the drive shaft plays a significant role in both power transfer efficiency and balance. Drive shafts are engineered to have appropriate dimensions, including diameter and wall thickness, to handle the anticipated torque loads without excessive deflection or vibration. The design also considers factors such as the length of the drive shaft, the number and type of joints (such as universal joints or constant velocity joints), and the use of balancing weights. By carefully designing the drive shaft, manufacturers can achieve optimal power transfer efficiency while minimizing the potential for imbalance-induced vibrations.

3. Balancing Techniques:

Balance is crucial for drive shafts as any imbalance can cause vibrations, noise, and accelerated wear. To maintain balance, drive shafts undergo various balancing techniques during the manufacturing process. Static and dynamic balancing methods are employed to ensure that the mass distribution along the drive shaft is uniform. Static balancing involves adding counterweights at specific locations to offset any weight imbalances. Dynamic balancing is performed by spinning the drive shaft at high speeds and measuring any vibrations. If imbalances are detected, additional adjustments are made to achieve a balanced state. These balancing techniques help minimize vibrations and ensure smooth operation of the drive shaft.

4. Universal Joints and Constant Velocity Joints:

Drive shafts often incorporate universal joints (U-joints) or constant velocity (CV) joints to accommodate misalignment and maintain balance during operation. U-joints are flexible joints that allow for angular movement between shafts. They are typically used in applications where the drive shaft operates at varying angles. CV joints, on the other hand, are designed to maintain a constant velocity of rotation and are commonly used in front-wheel-drive vehicles. By incorporating these joints, drive shafts can compensate for misalignment, reduce stress on the shaft, and minimize vibrations that can negatively impact power transfer efficiency and balance.

5. Maintenance and Inspection:

Regular maintenance and inspection of drive shafts are essential for ensuring efficient power transfer and balance. Periodic checks for wear, damage, or misalignment can help identify any issues that may affect the drive shaft’s performance. Lubrication of the joints and proper tightening of fasteners are also critical for maintaining optimal operation. By adhering to recommended maintenance procedures, any imbalances or inefficiencies can be addressed promptly, ensuring continued efficient power transfer and balance.

In summary, drive shafts ensure efficient power transfer while maintaining balance through careful material selection, thoughtful design considerations, balancing techniques, and the incorporation of flexible joints. By optimizing these factors, drive shafts can transmit rotational power smoothly and reliably, minimizing energy losses and vibrations that can impact performance and longevity.

How do drive shafts contribute to the efficiency of vehicle propulsion and power transmission?

Drive shafts play a crucial role in the efficiency of vehicle propulsion and power transmission systems. They are responsible for transferring power from the engine or power source to the wheels or driven components. Here’s a detailed explanation of how drive shafts contribute to the efficiency of vehicle propulsion and power transmission:

1. Power Transfer:

Drive shafts transmit power from the engine or power source to the wheels or driven components. By efficiently transferring rotational energy, drive shafts enable the vehicle to move forward or drive the machinery. The design and construction of drive shafts ensure minimal power loss during the transfer process, maximizing the efficiency of power transmission.

2. Torque Conversion:

Drive shafts can convert torque from the engine or power source to the wheels or driven components. Torque conversion is necessary to match the power characteristics of the engine with the requirements of the vehicle or machinery. Drive shafts with appropriate torque conversion capabilities ensure that the power delivered to the wheels is optimized for efficient propulsion and performance.

3. Constant Velocity (CV) Joints:

Many drive shafts incorporate Constant Velocity (CV) joints, which help maintain a constant speed and efficient power transmission, even when the driving and driven components are at different angles. CV joints allow for smooth power transfer and minimize vibration or power losses that may occur due to changing operating angles. By maintaining constant velocity, drive shafts contribute to efficient power transmission and improved overall vehicle performance.

4. Lightweight Construction:

Efficient drive shafts are often designed with lightweight materials, such as aluminum or composite materials. Lightweight construction reduces the rotational mass of the drive shaft, which results in lower inertia and improved efficiency. Reduced rotational mass enables the engine to accelerate and decelerate more quickly, allowing for better fuel efficiency and overall vehicle performance.

5. Minimized Friction:

Efficient drive shafts are engineered to minimize frictional losses during power transmission. They incorporate features such as high-quality bearings, low-friction seals, and proper lubrication to reduce energy losses caused by friction. By minimizing friction, drive shafts enhance power transmission efficiency and maximize the available power for propulsion or operating other machinery.

6. Balanced and Vibration-Free Operation:

Drive shafts undergo dynamic balancing during the manufacturing process to ensure smooth and vibration-free operation. Imbalances in the drive shaft can lead to power losses, increased wear, and vibrations that reduce overall efficiency. By balancing the drive shaft, it can spin evenly, minimizing vibrations and optimizing power transmission efficiency.

7. Maintenance and Regular Inspection:

Proper maintenance and regular inspection of drive shafts are essential for maintaining their efficiency. Regular lubrication, inspection of joints and components, and prompt repair or replacement of worn or damaged parts help ensure optimal power transmission efficiency. Well-maintained drive shafts operate with minimal friction, reduced power losses, and improved overall efficiency.

8. Integration with Efficient Transmission Systems:

Drive shafts work in conjunction with efficient transmission systems, such as manual, automatic, or continuously variable transmissions. These transmissions help optimize power delivery and gear ratios based on driving conditions and vehicle speed. By integrating with efficient transmission systems, drive shafts contribute to the overall efficiency of the vehicle propulsion and power transmission system.

9. Aerodynamic Considerations:

In some cases, drive shafts are designed with aerodynamic considerations in mind. Streamlined drive shafts, often used in high-performance or electric vehicles, minimize drag and air resistance to improve overall vehicle efficiency. By reducing aerodynamic drag, drive shafts contribute to the efficient propulsion and power transmission of the vehicle.

10. Optimized Length and Design:

Drive shafts are designed to have optimal lengths and designs to minimize energy losses. Excessive drive shaft length or improper design can introduce additional rotational mass, increase bending stresses, and result in energy losses. By optimizing the length and design, drive shafts maximize power transmission efficiency and contribute to improved overall vehicle efficiency.

Overall, drive shafts contribute to the efficiency of vehicle propulsion and power transmission through effective power transfer, torque conversion, utilization of CV joints, lightweight construction, minimized friction, balanced operation, regular maintenance, integration with efficient transmission systems, aerodynamic considerations, and optimized length and design. By ensuring efficient power delivery and minimizing energy losses, drive shafts play a significant role in enhancing the overall efficiency and performance of vehicles and machinery.

How do drive shafts contribute to transferring rotational power in various applications?

Drive shafts play a crucial role in transferring rotational power from the engine or power source to the wheels or driven components in various applications. Whether it’s in vehicles or machinery, drive shafts enable efficient power transmission and facilitate the functioning of different systems. Here’s a detailed explanation of how drive shafts contribute to transferring rotational power:

1. Vehicle Applications:

In vehicles, drive shafts are responsible for transmitting rotational power from the engine to the wheels, enabling the vehicle to move. The drive shaft connects the gearbox or transmission output shaft to the differential, which further distributes the power to the wheels. As the engine generates torque, it is transferred through the drive shaft to the wheels, propelling the vehicle forward. This power transfer allows the vehicle to accelerate, maintain speed, and overcome resistance, such as friction and inclines.

2. Machinery Applications:

In machinery, drive shafts are utilized to transfer rotational power from the engine or motor to various driven components. For example, in industrial machinery, drive shafts may be used to transmit power to pumps, generators, conveyors, or other mechanical systems. In agricultural machinery, drive shafts are commonly employed to connect the power source to equipment such as harvesters, balers, or irrigation systems. Drive shafts enable these machines to perform their intended functions by delivering rotational power to the necessary components.

3. Power Transmission:

Drive shafts are designed to transmit rotational power efficiently and reliably. They are capable of transferring substantial amounts of torque from the engine to the wheels or driven components. The torque generated by the engine is transmitted through the drive shaft without significant power losses. By maintaining a rigid connection between the engine and the driven components, drive shafts ensure that the power produced by the engine is effectively utilized in performing useful work.

4. Flexible Coupling:

One of the key functions of drive shafts is to provide a flexible coupling between the engine/transmission and the wheels or driven components. This flexibility allows the drive shaft to accommodate angular movement and compensate for misalignment between the engine and the driven system. In vehicles, as the suspension system moves or the wheels encounter uneven terrain, the drive shaft adjusts its length and angle to maintain a constant power transfer. This flexibility helps prevent excessive stress on the drivetrain components and ensures smooth power transmission.

5. Torque and Speed Transmission:

Drive shafts are responsible for transmitting both torque and rotational speed. Torque is the rotational force generated by the engine or power source, while rotational speed is the number of revolutions per minute (RPM). Drive shafts must be capable of handling the torque requirements of the application without excessive twisting or bending. Additionally, they need to maintain the desired rotational speed to ensure the proper functioning of the driven components. Proper design, material selection, and balancing of the drive shafts contribute to efficient torque and speed transmission.

6. Length and Balance:

The length and balance of drive shafts are critical factors in their performance. The length of the drive shaft is determined by the distance between the engine or power source and the driven components. It should be appropriately sized to avoid excessive vibrations or bending. Drive shafts are carefully balanced to minimize vibrations and rotational imbalances, which can affect the overall performance, comfort, and longevity of the drivetrain system.

7. Safety and Maintenance:

Drive shafts require proper safety measures and regular maintenance. In vehicles, drive shafts are often enclosed within a protective tube or housing to prevent contact with moving parts, reducing the risk of injury. Safety shields or guards may also be installed around exposed drive shafts in machinery to protect operators from potential hazards. Regular maintenance includes inspecting the drive shaft for wear, damage, or misalignment, and ensuring proper lubrication of the U-joints. These measures help prevent failures, ensure optimal performance, and extend the service life of the drive shaft.

In summary, drive shafts play a vital role in transferring rotational power in various applications. Whether in vehicles or machinery, drive shafts enable efficient power transmission from the engine or power source to the wheels or driven components. They provide a flexible coupling, handle torque and speed transmission, accommodate angular movement, and contribute to the safety and maintenance of the system. By effectively transferring rotational power, drive shafts facilitate the functioning and performance of vehicles and machinery in numerous industries.

editor by CX 2024-03-18

China supplier Custom CNC Turning Steel Alloy Swing Motor Transmission Drive Pinion Gear Shaft

Product Description

Company Profile

Workshop

Detailed Photos

Product Description

| Material | Alloy Steel, Copper alloy(brass,silicon bronze,phosphor bronze,aluminum bronze,beryllium copper),Stainless Steel,Aluminum,Titanium, Magnesium, Superalloys,Molybdenum, Invar,,Zinc,Tungsten steel,incoloy,Nickel 200,Hastelloy, Inconel,Monel,ABS, PEEK,PTFE,PVC,Acetal. |

| Surface Treatment | Zn-plating, Ni-plating, Cr-plating, Tin-plating, copper-plating, the wreath oxygen resin spraying, the heat disposing, hot-dip galvanizing, black oxide coating, painting, powdering, color zinc-plated, blue black zinc-plated, rust preventive oil, titanium alloy galvanized, silver plating, plastic, electroplating, anodizing etc. |

| Producing Equipment | CNC machine,automatic lathe machine,CNC milling machine,lasering,tag grinding machine etc. |

| Drawing Format | Pro/E, Auto CAD, CZPT Works, UG, CAD/CAM, PDF |

| Managing Returned Goods | With quality problem or deviation from drawings |

| Warranty | Replacement at all our cost for rejected products |

| Main Markets | North America, South America, Eastern Europe , West Europe , North Europe, South Europe, Asia |

| How to order | * You send us drawing or sample |

| * We carry through project assessment | |

| * We make the sample and send it to you after you confirmed our design | |

| * You confirm the sample then place an order and pay us 30% deposit | |

| * We start producing | |

| * When the goods is done, you pay us the balance after you confirmed pictures or tracking numbers. | |

| * Trade is done, thank you!! |

Quality Control

Packaging & Shipping

Customer Reviews

FAQ

Q1:What kind of information do you need for quotation?

A: You can provide 2D/3D drawing or send your sample to our factory, then we can make according to your sample.

Q2: Can we CZPT NDA?

A: Sure. We can CZPT the NDA before got your drawings.

Q3: Do you provide sample?

A: Yes, we can provide you sample before mass order.

Q4: How can you ensure the quality?

A: We have profesional QC,IQC, OQC to guarantee the quality.

Q5: Delivery time?

A: For samples genearlly need 25 days. Mass production: around 30~45 days after receipt of deposit (Accurate delivery time

depends on specific items and quantities)

Q6: How about the transportation?

A: You can choose any mode of transportation you want, sea delivery, air delivery or door to door express.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Alloy Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | IT6-IT9 |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Real Axis |

| Customization: |

Available

| Customized Request |

|---|

How do manufacturers ensure the compatibility of drive shafts with different equipment?

Manufacturers employ various strategies and processes to ensure the compatibility of drive shafts with different equipment. Compatibility refers to the ability of a drive shaft to effectively integrate and function within a specific piece of equipment or machinery. Manufacturers take into account several factors to ensure compatibility, including dimensional requirements, torque capacity, operating conditions, and specific application needs. Here’s a detailed explanation of how manufacturers ensure the compatibility of drive shafts:

1. Application Analysis:

Manufacturers begin by conducting a thorough analysis of the intended application and equipment requirements. This analysis involves understanding the specific torque and speed demands, operating conditions (such as temperature, vibration levels, and environmental factors), and any unique characteristics or constraints of the equipment. By gaining a comprehensive understanding of the application, manufacturers can tailor the design and specifications of the drive shaft to ensure compatibility.

2. Customization and Design:

Manufacturers often offer customization options to adapt drive shafts to different equipment. This customization involves tailoring the dimensions, materials, joint configurations, and other parameters to match the specific requirements of the equipment. By working closely with the equipment manufacturer or end-user, manufacturers can design drive shafts that align with the equipment’s mechanical interfaces, mounting points, available space, and other constraints. Customization ensures that the drive shaft fits seamlessly into the equipment, promoting compatibility and optimal performance.

3. Torque and Power Capacity:

Drive shaft manufacturers carefully determine the torque and power capacity of their products to ensure compatibility with different equipment. They consider factors such as the maximum torque requirements of the equipment, the expected operating conditions, and the safety margins necessary to withstand transient loads. By engineering drive shafts with appropriate torque ratings and power capacities, manufacturers ensure that the shaft can handle the demands of the equipment without experiencing premature failure or performance issues.

4. Material Selection:

Manufacturers choose materials for drive shafts based on the specific needs of different equipment. Factors such as torque capacity, operating temperature, corrosion resistance, and weight requirements influence material selection. Drive shafts may be made from various materials, including steel, aluminum alloys, or specialized composites, to provide the necessary strength, durability, and performance characteristics. The selected materials ensure compatibility with the equipment’s operating conditions, load requirements, and other environmental factors.

5. Joint Configurations:

Drive shafts incorporate joint configurations, such as universal joints (U-joints) or constant velocity (CV) joints, to accommodate different equipment needs. Manufacturers select and design the appropriate joint configuration based on factors such as operating angles, misalignment tolerances, and the desired level of smooth power transmission. The choice of joint configuration ensures that the drive shaft can effectively transmit power and accommodate the range of motion required by the equipment, promoting compatibility and reliable operation.

6. Quality Control and Testing:

Manufacturers implement stringent quality control processes and testing procedures to verify the compatibility of drive shafts with different equipment. These processes involve conducting dimensional inspections, material testing, torque and stress analysis, and performance testing under simulated operating conditions. By subjecting drive shafts to rigorous quality control measures, manufacturers can ensure that they meet the required specifications and performance criteria, guaranteeing compatibility with the intended equipment.

7. Compliance with Standards:

Manufacturers ensure that their drive shafts comply with relevant industry standards and regulations. Compliance with standards, such as ISO (International Organization for Standardization) or specific industry standards, provides assurance of quality, safety, and compatibility. Adhering to these standards helps manufacturers meet the expectations and requirements of equipment manufacturers and end-users, ensuring that the drive shafts are compatible and can be seamlessly integrated into different equipment.

8. Collaboration and Feedback:

Manufacturers often collaborate closely with equipment manufacturers, OEMs (Original Equipment Manufacturers), or end-users to gather feedback and incorporate their specific requirements into the drive shaft design and manufacturing processes. This collaborative approach ensures that the drive shafts are compatible with the intended equipment and meet the expectations of the end-users. By actively seeking input and feedback, manufacturers can continuously improve their products’ compatibility and performance.

In summary, manufacturers ensure the compatibility of drive shafts with different equipment through a combination of application analysis, customization, torque and power capacity considerations, material selection, joint configurations, quality control and testing, compliance with standards, and collaboration with equipment manufacturers and end-users. These efforts enable manufacturers to design and produce drive shafts that seamlessly integrate with various equipment, ensuring optimal performance, reliability, and compatibility in different applications.

How do drive shafts enhance the performance of automobiles and trucks?

Drive shafts play a significant role in enhancing the performance of automobiles and trucks. They contribute to various aspects of vehicle performance, including power delivery, traction, handling, and overall efficiency. Here’s a detailed explanation of how drive shafts enhance the performance of automobiles and trucks:

1. Power Delivery: Drive shafts are responsible for transmitting power from the engine to the wheels, enabling the vehicle to move forward. By efficiently transferring power without significant losses, drive shafts ensure that the engine’s power is effectively utilized, resulting in improved acceleration and overall performance. Well-designed drive shafts with minimal power loss contribute to the vehicle’s ability to deliver power to the wheels efficiently.

2. Torque Transfer: Drive shafts facilitate the transfer of torque from the engine to the wheels. Torque is the rotational force that drives the vehicle forward. High-quality drive shafts with proper torque conversion capabilities ensure that the torque generated by the engine is effectively transmitted to the wheels. This enhances the vehicle’s ability to accelerate quickly, tow heavy loads, and climb steep gradients, thereby improving overall performance.

3. Traction and Stability: Drive shafts contribute to the traction and stability of automobiles and trucks. They transmit power to the wheels, allowing them to exert force on the road surface. This enables the vehicle to maintain traction, especially during acceleration or when driving on slippery or uneven terrain. The efficient power delivery through the drive shafts enhances the vehicle’s stability by ensuring balanced power distribution to all wheels, improving control and handling.

4. Handling and Maneuverability: Drive shafts have an impact on the handling and maneuverability of vehicles. They help establish a direct connection between the engine and the wheels, allowing for precise control and responsive handling. Well-designed drive shafts with minimal play or backlash contribute to a more direct and immediate response to driver inputs, enhancing the vehicle’s agility and maneuverability.

5. Weight Reduction: Drive shafts can contribute to weight reduction in automobiles and trucks. Lightweight drive shafts made from materials such as aluminum or carbon fiber-reinforced composites reduce the overall weight of the vehicle. The reduced weight improves the power-to-weight ratio, resulting in better acceleration, handling, and fuel efficiency. Additionally, lightweight drive shafts reduce the rotational mass, allowing the engine to rev up more quickly, further enhancing performance.

6. Mechanical Efficiency: Efficient drive shafts minimize energy losses during power transmission. By incorporating features such as high-quality bearings, low-friction seals, and optimized lubrication, drive shafts reduce friction and minimize power losses due to internal resistance. This enhances the mechanical efficiency of the drivetrain system, allowing more power to reach the wheels and improving overall vehicle performance.

7. Performance Upgrades: Drive shaft upgrades can be popular performance enhancements for enthusiasts. Upgraded drive shafts, such as those made from stronger materials or with enhanced torque capacity, can handle higher power outputs from modified engines. These upgrades allow for increased performance, such as improved acceleration, higher top speeds, and better overall driving dynamics.

8. Compatibility with Performance Modifications: Performance modifications, such as engine upgrades, increased power output, or changes to the drivetrain system, often require compatible drive shafts. Drive shafts designed to handle higher torque loads or adapt to modified drivetrain configurations ensure optimal performance and reliability. They enable the vehicle to effectively harness the increased power and torque, resulting in improved performance and responsiveness.

9. Durability and Reliability: Robust and well-maintained drive shafts contribute to the durability and reliability of automobiles and trucks. They are designed to withstand the stresses and loads associated with power transmission. High-quality materials, appropriate balancing, and regular maintenance help ensure that drive shafts operate smoothly, minimizing the risk of failures or performance issues. Reliable drive shafts enhance the overall performance by providing consistent power delivery and minimizing downtime.

10. Compatibility with Advanced Technologies: Drive shafts are evolving in tandem with advancements in vehicle technologies. They are increasingly being integrated with advanced systems such as hybrid powertrains, electric motors, and regenerative braking. Drive shafts designed to work seamlessly with these technologies maximize their efficiency and performance benefits, contributing to improved overall vehicle performance.

In summary, drive shafts enhance the performance of automobiles and trucks by optimizing power delivery, facilitating torque transfer, improving traction and stability, enhancing handling and maneuverability, reducing weight, increasing mechanical efficiency, enabling compatibility with performance upgrades and advanced technologies, and ensuring durability and reliability. They play a crucial role in ensuring efficient power transmission, responsive acceleration, precise handling, and overall improved performance of vehicles.

How do drive shafts handle variations in length and torque requirements?

Drive shafts are designed to handle variations in length and torque requirements in order to efficiently transmit rotational power. Here’s an explanation of how drive shafts address these variations:

Length Variations:

Drive shafts are available in different lengths to accommodate varying distances between the engine or power source and the driven components. They can be custom-made or purchased in standardized lengths, depending on the specific application. In situations where the distance between the engine and the driven components is longer, multiple drive shafts with appropriate couplings or universal joints can be used to bridge the gap. These additional drive shafts effectively extend the overall length of the power transmission system.

Additionally, some drive shafts are designed with telescopic sections. These sections can be extended or retracted, allowing for adjustments in length to accommodate different vehicle configurations or dynamic movements. Telescopic drive shafts are commonly used in applications where the distance between the engine and the driven components may change, such as in certain types of trucks, buses, and off-road vehicles.

Torque Requirements:

Drive shafts are engineered to handle varying torque requirements based on the power output of the engine or power source and the demands of the driven components. The torque transmitted through the drive shaft depends on factors such as the engine power, load conditions, and the resistance encountered by the driven components.

Manufacturers consider torque requirements when selecting the appropriate materials and dimensions for drive shafts. Drive shafts are typically made from high-strength materials, such as steel or aluminum alloys, to withstand the torque loads without deformation or failure. The diameter, wall thickness, and design of the drive shaft are carefully calculated to ensure it can handle the expected torque without excessive deflection or vibration.

In applications with high torque demands, such as heavy-duty trucks, industrial machinery, or performance vehicles, drive shafts may have additional reinforcements. These reinforcements can include thicker walls, cross-sectional shapes optimized for strength, or composite materials with superior torque-handling capabilities.

Furthermore, drive shafts often incorporate flexible joints, such as universal joints or constant velocity (CV) joints. These joints allow for angular misalignment and compensate for variations in the operating angles between the engine, transmission, and driven components. They also help absorb vibrations and shocks, reducing stress on the drive shaft and enhancing its torque-handling capacity.

In summary, drive shafts handle variations in length and torque requirements through customizable lengths, telescopic sections, appropriate materials and dimensions, and the inclusion of flexible joints. By carefully considering these factors, drive shafts can efficiently and reliably transmit power while accommodating the specific needs of different applications.

editor by CX 2024-03-11

in Busto Arsizio Italy sales price shop near me near me shop factory supplier High Precision CNC Stainless Steel Gear Shaft Which Transfer Power From Motor Shaft to Planetary Gearbox manufacturer best Cost Custom Cheap wholesaler

With in depth requirments, we can also create your specific created solution. We also can style and make non-normal goods to fulfill customers’ specific specifications. With several years’ experience in this line, we will be dependable by our rewards in competitive value, one particular-time shipping and delivery, prompt reaction, on-hand engineering assist and very good following-product sales providers.Additionally, all our production techniques are in compliance with ISO9001 standards.

1. Description

|

Product identify |

304 stainless steel shaft |

|

EPT |

Stainless Metal,EPTT,Brass, Bronze,EPTT metal and ect. environmental security materials. |

|

Size |

EPTT according to your drawing. |

|

Services |

OEM, design and style, EPT |

|

Tolerance |

/-.01mm to /-.005mm |

|

Surface treatment method |

Passivation *PoEPTTng *Anodizing *Sand blasting *Electroplating(colour, blue, white, black zinc, Ni, Cr, tin, copper, silver) *Black oXiHu (West EPT) Dis.de coating *Heat-disposing *Hot-dip galvanizing *Rust preventive oil |

|

MOQ |

1 piece Copper bushing |

|

Samples |

We can make sample in 7daEPTTfree of charge |

|

Certificate |

ISO9001:2015 cnc machining turning elements shaft |

|

Payment Conditions |

Financial institution TransferWestern EPT Paypal Payoneer, Alibaba EPT Assurance30% deposit amp equilibrium prior to shipping and delivery. |

|

Supply time |

Within 15-20 workdaEPTTafter deposit or payment EPTd |

|

EPT Port |

HangEPT 304 stainless metal shaft |

2. Major EPT Shafts

three. Function Movement

4. Software

5. About US

ATA uxcell double shaft worm gear motor shop made in China – replacement parts – in Geneva Switzerland Series Shaft Mounted Reduction Gearbox for Blender with top quality

We – EPG Group the greatest worm gearbox, couplings and gears manufacturing facility in China with 5 distinct branches. For much more information: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828 /

ATA Series Shaft Mounted Reduction Gearbox for Blender

Attribute

1. Very Standard Modular Developed

The goods are very easily connected with and driven by distinct sorts of motors or other types of input power. The very same type geared motor can be adapted to optioned powers of motors. It truly is for that reason easy to understand different solutions for different demands.

2. Large power, Compact dimension

Housings are manufactured of substantial energy forged iron. Gears and shaft gears are concluded with gasoline carburising method and specific grouding to sequentially get higher loading capability of percertain quantity.

three. Extended provider daily life

Underneath the situation of accurately variety type size and the regular routine maintenance and use, primary elements(count on individuals simply-disabled elements)can final as prolonged as up to much more than twenty five, 000hours. Very easily-disabled areas consist of lubricating oil, oil seals, and bearings.

four. Lower noise

All important elements are completed by specifically machining, accurate assembly, and last but not least analyzed, and for that reason, relatively low noise is reached.

five. Higher efficiency

The efficiency of equipment unit can reach ninety five%, The efficiency of worm gear device can reach 89%.

6. Large radial loading ability

seven. Axial load capacity of up to 5%of radial load

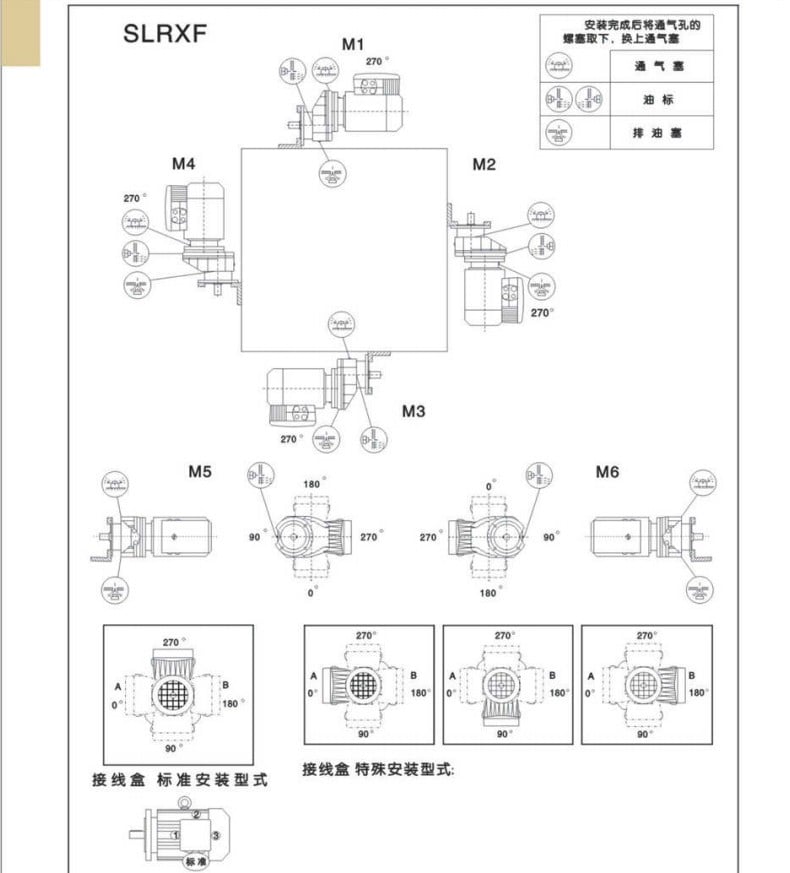

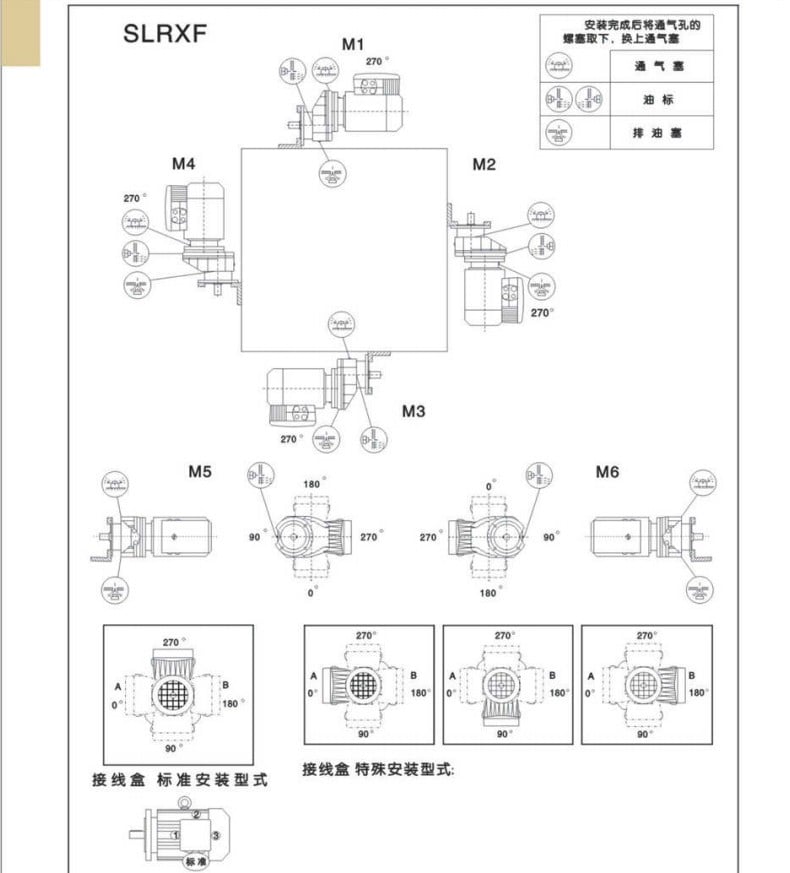

eight. Mounting Arrangemnet

No rigid limitation to the mounting arrangement.

9. Ratio

Showcased a lot of closely divided ratios and extensive assortment of them. Quite huge closing ratios can be attained by means of blended unites to achieve incredibly low output speeds.

Type Expression of GF Series

Notice:

1. Remember to make a be aware, if it wants connecting flange.

two. Contents of motors for enter shaft sorts are not listed

3. Degree=, if terminal box place is not talked about. It is X, if cable entry positon is not described.

four. If certain rotation directions of output shaft or/and enter shaft are specifically requested, you should get in touch with our engineering section, and make thorough description although putting order.

Mounting Preparations Description:

Various varieties of mounting preparations are outlined as subsequent:

M1- Horizontally mounted motor, device base is at bottom.

M2-motor is vertically mounted downwards.

M3- horizontally mounted motor, unit foundation is best.

M4- motor is vertically mounted upwards.

M5- horizontally mounted motor, if put on M1 placement, still left side of uni turns to botton(see point: Towards from motor aspect).

M6- horizontally mounted motor, if positioned on M1 place, remaining facet of device turns to top(look at point: Towards from motor aspect).

Item photos:

Product application:

Our company :

AOKMAN® was started in 1982, which has more than 36 many years in R & D and manufacturing of gearboxes, gears, shaft, motor and spare areas.

We can supply the suitable solution for uncountable purposes. Our merchandise are broadly employed in the ranges of metallurgical, metal, mining, pulp and paper, sugar and alcohol market place and different other varieties of equipment with a strong existence in the global marketplace.

AOKMAN® has grow to be a reliable provider, capable to supply high top quality gearboxes.With 36 years encounter, we guarantee you the utmost dependability and security for both product and providers.

Buyer going to:

Our Providers:

| Pre-sale providers | 1. Pick products product. |

| two.Layout and manufacture goods in accordance to clients’ particular necessity. | |

| three.Practice specialized personalized for consumers | |

| Services throughout selling | one.Pre-examine and accept merchandise in advance of delivery. |

| two. Aid clients to draft fixing plans. | |

| After-sale companies | one.Support customers to get ready for the very first design scheme. |

| two. Prepare the first-line operators. | |

| 3.Take initiative to eradicate the trouble swiftly. | |

| 4. Offer technological exchanging. |

FAQ:

one.Q:What varieties of gearbox can you create for us?

A:Major merchandise of our business: UDL collection velocity variator,RV series worm equipment reducer, ATA sequence shaft mounted gearbox, X,B series equipment reducer,

P sequence planetary gearbox and R, S, K, and F series helical-tooth reducer, a lot more

than 1 hundred versions and thousands of requirements

two.Q:Can you make as per personalized drawing?

A: Yes, we offer custom-made services for clients.

3.Q:What is your conditions of payment ?

A: thirty% ept payment by T/T soon after signing the deal.70% ahead of supply

4.Q:What is your MOQ?

A: 1 Set

If you have any need for our items remember to really feel free of charge to get in touch with me

/ The use of unique tools manufacturer’s (OEM) part numbers or trademarks , e.g. CASE® and John Deere® are for reference needs only and for indicating product use and compatibility. Our firm and the listed replacement components contained herein are not sponsored, accredited, or made by the OEM. /

S 4 pole induction motor speed wholesaler made in China – replacement parts – in Chelyabinsk Russian Federation Series Foot Mounted Helical Worm Gear Box with Hollow Shaft with top quality

We – EPG Group the largest worm gearbox, couplings and gears manufacturing facility in China with 5 distinct branches. For a lot more details: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828 /

| Kind: | S series Helical Worm Equipment Motors |

| Design: | S37-S97 |

| Brand name title: | YBANG |

| Coloration: | Blue/Gray or on ask for |

| Content: | HT250 |

| Input electrical power: | .12-22kw |

| Output torque: | eleven-4900N.m |

| Output speed: | .12-397rpm |

| Bearing: | C&U Bearing,NSK,SKF or on ask for |

| Seal: | SKF,CTY,CFW or on ask for |

| Origin: | ZHangZhoug, China |

| Guarantee: | one 12 months |

Functions of merchandise

1. Very Common Modular Made: The items are easily linked with and driven by different sorts of motors and various input electricity. The identical kind geared motor can be adapted to optioned powers of motors. It is for that reason simple to recognize diverse answer for different requirements.

two. Ratio: Featured many closely divided ratios and broad assortment of them. Extremely huge closing ratios can be acquired through merged unites to attain extremely lower output speeds.

three. Mounting Arrangement: No rigid limitation to the mounting arrangement.

4. High Energy, Compact Dimension: Housings are created of high energy solid iron. Gears and shaft gears are completed with fuel carburizing approach and precise grounding to sequentially get higher loading ability of for each specific quantity.

five. Prolonged Services Existence: Under the issue of precisely selecting sort size and the normal maintenance and use, main elements (expect individuals simply-disabled components) can last as lengthy as up to far more than twenty five,000 hours. Easily-disabled elements incorporate lubricating oil, oil seals, and bearings.

6. Minimal Noise: All crucial components are finished by exactly machining, precise assembly, and last but not least analyzed, and for that reason, relatively minimal sounds is attained.

seven. Large Performance: The performance of equipment unit can reach 95%, The performance of worm gear unit can attain 89%.

8. Massive radial loading potential.

nine. Axial load potential of up to 5% of radial load.

(1) With excellent good quality and Realistic value

(2) Guarantee to supply on time

(3) Risk-free, reputable, economical and sturdy

(4) Steady transmission, quiet operation

(5) Substantial warmth-radiating performance, substantial carrying capacity

(6) Each and every item should be examined before sending

/ The use of original tools manufacturer’s (OEM) portion numbers or trademarks , e.g. CASE® and John Deere® are for reference reasons only and for indicating solution use and compatibility. Our firm and the listed replacement parts contained herein are not sponsored, approved, or made by the OEM. /

60mm Cheap made in China – replacement parts – in Huambo Angola Gear Motor Constant Speed 6W 220V 8mm Shaft 2rk6gn-C 2gn3K-180K with top quality

We – EPG Group the most significant gearbox & motors , couplings and gears manufacturing unit in China with 5 different branches. For far more information: Cell/whatsapp/telegram/Kakao us at: 0086~13 571 88828 13858117778 571 88828

TaiBang Motor Industrial Team Co., Ltd.

The primary products is induction motor, reversible motor, DC brush equipment motor, DC brushless gear motor, CH/CV huge equipment motors, Planetary equipment motor ,Worm equipment motor etc, which utilized extensively in numerous fields of producing pipelining, transportation, food, medication, printing, material, packing, business office, equipment, entertainment and so forth, and is the desired and matched product for automatic equipment.

6W 60mm constant speed AC gear motor

| Specification of motor 6W 60mm Fixed velocity AC equipment motor | ||||||||||||

| TYPE | Gear tooth Output Shaft | Power (W) |

Frequency (Hz) |

Voltage (V) |

Current (A) |

Start Torque (g.cm) |

Rated | Start | Gearbox kind | |||

| Torque (g.cm) |

Velocity (rpm) |

Capability (μF) |

Resistance Voltage (V) |

Bearing gearbox | Center Gearbox | |||||||

| Reversible Motor | 2RK6GN-C | 6 | 50 | 220 | .12 | 600 | 487 | 1200 | .8 | 500 | 2GN- K | 2GN10X |

| six | sixty | 220 | .11 | five hundred | 400 | 1450 | .7 | five hundred | 2GN- K | 2GN10X | ||

Drawing: 2RK6GN-C/2GN3~20K (Brief gearbox shell 32mm)

Drawing: 2RK6GN-C/2GN25~180K (Short gearbox shell 40mm)

| Gearbox torque desk(Kg.cm) | (kg.cm×9.8÷100)=N.m | |||||||||||||||||||

| Output speed :RPM | 500 | 300 | two hundred | a hundred and fifty | one hundred twenty | 100 | seventy five | sixty | 50 | 30 | twenty | 15 | ten | seven.5 | six | five | 3 | |||

| Speed ratio | 50Hz | three | five | 7.5 | ten | 12.5 | fifteen | twenty | twenty five | thirty | fifty | seventy five | one hundred | a hundred and fifty | two hundred | 250 | 300 | five hundred | ||

| 60Hz | three.6 | six | 9 | fifteen | eighteen | thirty | 36 | 60 | 90 | 120 | 180 | three hundred | 360 | 600 | ||||||

| Allowed torque |

4W | kg.cm | .66 | one.one | 1.seven | 2.two | 2.seven | three.3 | 4.4 | 5.4 | six.five | 10.seven | 15 | 20 | twenty five | twenty five | twenty five | 25 | 25 | |

| 6W | kg.cm | one. | one.6 | 2.five | 3.3 | four.one | 5 | six.6 | 8.one | 9.7 | 16 | 23 | 25 | 25 | 25 | twenty five | 25 | twenty five | ||

| 10W | kg.cm | one.7 | 2.seven | four.two | 5.five | 6.eight | eight.three | eleven | thirteen.five | sixteen | 25 | 25 | twenty five | 25 | 25 | 25 | twenty five | 25 | ||

| Note: Pace figures are based on synchronous speed, The real output pace, below rated torque problems, is about 10-20% much less than synchronous pace, a grey track record signifies output shaft of geared motor rotates in the same path as output shaft of motor. A white history indicates rotates rotation in the opposite course. | ||||||||||||||||||||

Drawing is for common screw hole, If need through gap, terminal box, or digital magnet brake, want to inform the seller.

| Basic tech info: | Retail value: |

| Motor sort: AC gear motor | Insulation Class:E |

| Motor substance:Aluminum ,Copper,Metal | IP quality:IP44 |

| Rotation:CW/CCW reversible | Working fashion:S1 |

| Frequency: 50Hz/60Hz | Operating temperature range: -ten °C~+40°C |

| HS Code:8501400000 | Running relative humidity: ninety five% Below |

Link Diagram:

Note

Specs for reference only.

Shaft dimension and specs(voltage,torque,pace,and many others) can be customized.

Welcome your check out and enquiry to our manufacturing unit!

The use of unique gear manufacturer’s (OEM) component figures or trademarks , e.g. CASE® and John Deere® are for reference reasons only and for indicating item use and compatibility. Our organization and the outlined substitute elements contained herein are not sponsored, approved, or created by the OEM.

Best China manufacturer & factory S series 90 degree hollow shaft helical gear reducer warm gearbox motor for agricultural machine With high quality best price

The product well displays environmental protection and energy saving.

Overview

Quick Details

- Applicable Industries:

-

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, farms, Energy & Mining, Construction works

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Gearing Arrangement:

-

worm

- Output Torque:

-

100~62800N.m

- Input Speed:

-

1450/960rpm

- Output Speed:

-

14-280rpm

- Ratio:

-

7.5~100

- Certification:

-

ISO9001-2008

- Mount Position:

-

Foot Mounted

- Bearing:

-

LYC,ZWZ

Supply Ability

- Supply Ability:

- 3000 Unit/Units per Month

Packaging & Delivery

- Packaging Details

- Wooden boxes , Cantons packed in 1 pallet

- Port

- Ningbo Port, Shanghai Port

Online Customization

S series 90 degree hollow shaft helical gear reducer warm gearbox motor for agricultural machine

Product Description

S series is one kind of Helical worm gearbox ,designed as Modularization and high-stainless cast iron case . It is combination of Close up of shear pin which will shear in half if the implement is subject to sufficient resistance Shear pin: the shear pin shaft I use for the chipper/shredder. The driven end yoke is actually two pieces with a shear pin or bolt that holds the two pieces as one during operation. Should the equipment encounter a sudden stop the pin will take the shock and “shear off” preventing any driveline damage. helical gear and worm gear ,which with higher efficiency and strength than simple aluminum worm gearbox . Due to their outstanding efficiency, these drives can be used in every industrial sector and tailored to individual torque and speed requirements. The gear ratios afforded by the helical-worm gear stage and the low noise levels during operation make these gearmotors ideal low-cost solutions for simple applications

Specifications:

1) Output speed: 0.6~1,028r/min

2) Output torque: up to 4530N.m

3) Motor powSeries P Precision Planetary Gearhead Series P high precision inline planetary servo drive will satisfy your most demanding automation applications. The compact, cube design, universal housing with precision bearings and precision honed planetary gearing provides high torque density while offering high positioning performance. Series P offers exact ratios from 3:1 through 40:1 with the highest efficiency and lowest backlash in the industry.er: 0.12~22kW

4) Mounted form: foot-mounted and flange-mounted mounting

|

Product Name |

Helical worm gear motor S series gear reducer reduction gearbox |

|

Gear Material |

20CrMnTi |

|

Case Material |

HT250 |

|

Shaft Material |

20CrMnTi |

|

Gear Processing |

Grinding finish by HOFLER Grinding Machines |

|

Color |

Customized |

|

Noise Test |

Bellow 65dB |

|

Machining precision of gears |

accurate grinding, 6 Grade |

|

Heat treatment |

tempering, cementiting, quenching,etc. |

|

Brand of bearings |

C&U ,HRB,LYC,ZWZ.SKF,NSK |

|

Brand of oil seal |

NAK or other brand |

|

Noise (MAX) |

65~70dB |

|

Temp. rise (MAX) |

40 C |

|

Temp. rise (Oil)(MAX) |

50 C |

Company Information

Certifications

Our Services

Packaging & Shipping

Related Products

FAQ

: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: DOur company is located in XiHu HangZhou Zhejiang Province. To you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

Contact us