Product Description

Description

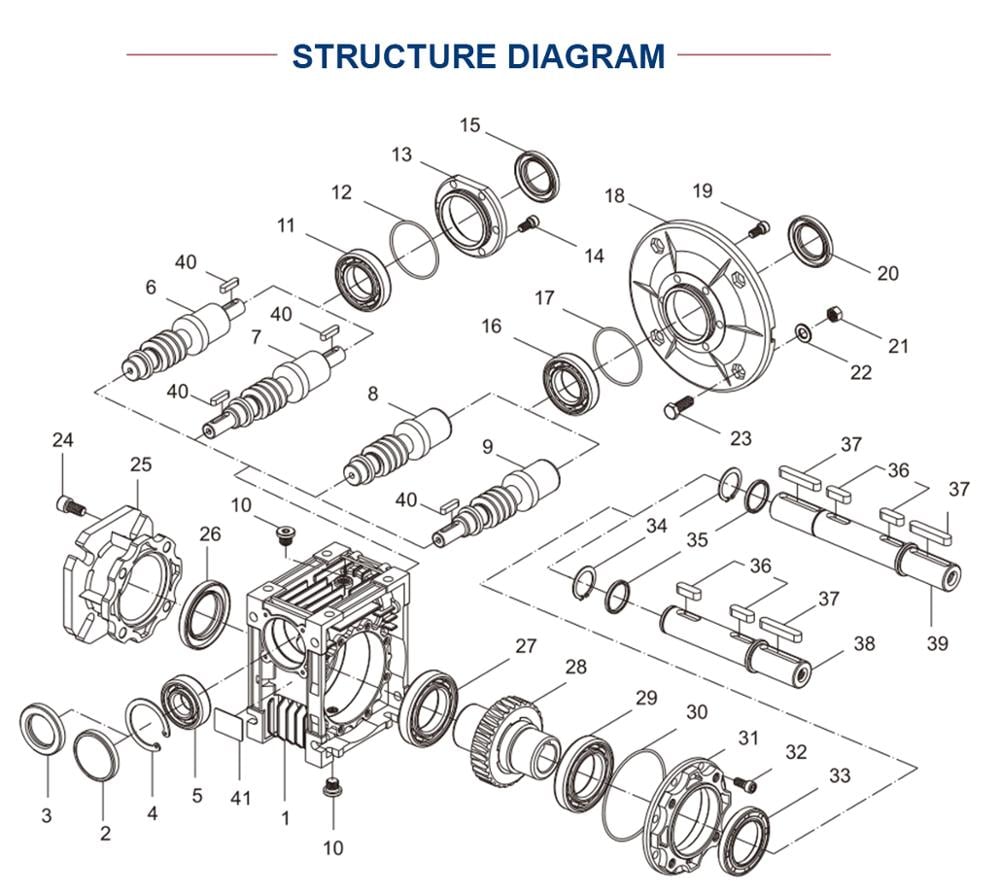

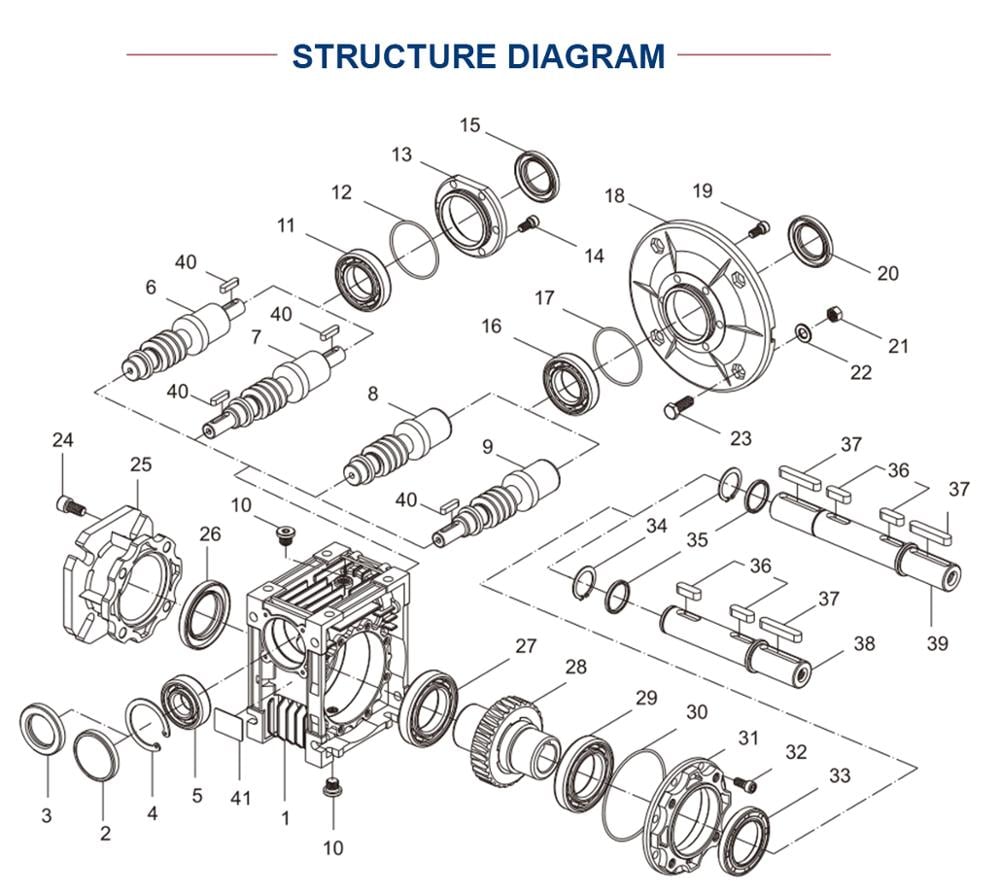

HDM De-clutchable wormgear offers simple and reliable manual positioning of the valves, dampers and other quarter-turn devices when overriding existing pneumatic, electric or hydraulic quarter-turn actuators. All unit are suitable for both indoor and outdoor installation. The modular design is to provide the most efficient and effective solution to a full range of manual overriding requirements.

Main Product features

To engage manual operation, first pull out the lock handle and then rotate the clutch lever in anti-clockwise direction until engagement takes place. To return to automatic mode, first pull out the lock handle and then rotate the clutch lever in clockwise.

Remark:The bottom center of the HDM-4 is either F10/F14 or F10/F12

| New Manual Override | Countershaft | Valve Connection | Actuator Connection | ||||||||||

| b1 | N | b2 | M | D1 | 4-M1 | D2 | 4-M2 | E | D3 | 4-Φ1 | D4 | 4-Φ2 | |

| HDM-1 | 14 | 22 | 14 | 16 | Φ50 | 4-M6 | Φ70 | 4-M8 | 70*70 | Φ50 | 4-Φ6.5 | Φ70 | 4-Φ8.5 |

| HDM-2 | 17 | 22 | 17 | 18 | Φ70 | 4-M8 | Φ102 | 4-M10 | 95*95 | Φ70 | 4-Φ8.5 | Φ102 | 4-Φ10.5 |

| HDM-3 | 22 | 28 | 22 | 22 | Φ102 | 4-M10 | Φ125 | 4-M12 | 114*114 | Φ102 | 4-Φ10.5 | Φ125 | 4-Φ12.5 |

| HDM-4 | 27 | 32 | 27 | 30 | Φ102 | 4-M10 | Φ125 | 4-M12 | 129*129 | Φ125 | 4-Φ12.5 | Φ140 | 4-Φ16.5 |

| HDM-5 | 36 | 45 | 36 | 38 | Φ140 | 4-M16 | / | / | 156*156 | Φ140 | 4-Φ17 | Φ165 | 4-Φ21 |

| HDM-6 | 46 | 50 | 46 | 48 | Φ165 | 4-M20 | / | / | 160*160 | Φ165 | 4-Φ22 | / | / |

| New Manual Override | A | B | ΦC | F | T | Y | H | S | K | Ratio | Rated Input | Rated Onput |

| HDM-1 | 90 | 55 | Φ88 | 115 | 44 | 145 | 120 | 53 | 10 | 26:1 | Nm | 250Nm |

| HDM-2 | 125 | 64 | Φ110 | 135 | 62.5 | 178 | 133 | 56.5 | 13 | 28:1 | Nm | 450Nm |

| HDM-3 | 140 | 71 | Φ129 | 166 | 70 | 212 | 180 | 68.7 | 12.5 | 38:1 | Nm | 700Nm |

| HDM-4 | 188.5 | 93 | Φ174 | 202 | 94 | 280 | 195 | 84 | 15 | 54:1 | Nm | 1200Nm |

| HDM-5 | 222 | 110 | Φ205 | 245 | 110 | 315 | 225 | 92 | 15 | 80:1 | Nm | 2000Nm |

| HDM-6 | 252 | 120 | Φ275 | 280 | 125 | 320 | 252 | 102 | 15 | 78:1 | Nm | 3000Nm |

1. Question:What is your main products?

Answer:Our main products are Pneumatic Actuators, Electric Actuators, Actuated Valves And Valve actuators Accessories..

2. Question:Are you a trader or manufacturer ?

Answer: We are the pneumatic actuators and electric actuators manufacturer , we have ability to do the customization products with experienced team, And we have own factory and production line.

3. Question:How do your make the quality guarantee for actuators?

Answer:We have our own quality control system for incoming and outgoing of the materials, every product will be under controlled and tested before delivery to our customer , and we also provide 18 months guarantee ,beside we provide technical supporting .

4. Question:When can I receive the Price of valve actuators ?

Answer:We will give the Quotation Within 24 hours after we get your inquiry .Or Your can call or message us if it’s quite urgently.

5. Question:How to order our pneumatic actuators and electric actuators ?

Answer:Please send us your inquiry by Email, , etc. we need to know the following informations before giving the formal Quotation.

1) Product information in details, Quantity, Other requirements

2) Delivery time required

6. Question:How can I get a sample to check your quality?

Answer:Contact with our sales expert to arrange the sample delivery. Please send us the details of the sample before placing the order.

7. Question:Shall we pay the sample cost and transportation cost ?

Answer:We will provide the sample by free of charge. Your will bear the freight cost.

8. Question:How long to prepare the sample ?

Answer:Most of our products are under regular production and some of them we keep in stocks.

9. Question:How to delivery the sample to our place?

Answer:Your can provide your forwarders contacts if any, or we will arrange it for you.

10. Question:What about the delivery date if we place the formal order ?

Answer:Usually it takes 15~20days on the production .We know that on-time delivery is very crucial to our customers to meet dead-lines.

We monitor and expedite our supply chain to ensure that we delivery our products to our customers on-time all the time.

| Application: | Motor |

|---|---|

| Function: | Change Drive Direction, Speed Changing |

| Layout: | Coaxial |

| Hardness: | Soft Tooth Surface |

| Installation: | Torque Arm Type |

| Step: | Double-Step |

| Samples: |

US$ 50/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How to Replace the Drive Shaft

Several different functions in a vehicle are critical to its functioning, but the driveshaft is probably the part that needs to be understood the most. A damaged or damaged driveshaft can damage many other auto parts. This article will explain how this component works and some of the signs that it may need repair. This article is for the average person who wants to fix their car on their own but may not be familiar with mechanical repairs or even driveshaft mechanics. You can click the link below for more information.

Repair damaged driveshafts

If you own a car, you should know that the driveshaft is an integral part of the vehicle’s driveline. They ensure efficient transmission of power from the engine to the wheels and drive. However, if your driveshaft is damaged or cracked, your vehicle will not function properly. To keep your car safe and running at peak efficiency, you should have it repaired as soon as possible. Here are some simple steps to replace the drive shaft.

First, diagnose the cause of the drive shaft damage. If your car is making unusual noises, the driveshaft may be damaged. This is because worn bushings and bearings support the drive shaft. Therefore, the rotation of the drive shaft is affected. The noise will be squeaks, dings or rattles. Once the problem has been diagnosed, it is time to repair the damaged drive shaft.

Professionals can repair your driveshaft at relatively low cost. Costs vary depending on the type of drive shaft and its condition. Axle repairs can range from $300 to $1,000. Labor is usually only around $200. A simple repair can cost between $150 and $1700. You’ll save hundreds of dollars if you’re able to fix the problem yourself. You may need to spend a few more hours educating yourself about the problem before handing it over to a professional for proper diagnosis and repair.

The cost of repairing a damaged driveshaft varies by model and manufacturer. It can cost as much as $2,000 depending on parts and labor. While labor costs can vary, parts and labor are typically around $70. On average, a damaged driveshaft repair costs between $400 and $600. However, these parts can be more expensive than that. If you don’t want to spend money on unnecessarily expensive repairs, you may need to pay a little more.

Learn how drive shafts work

While a car engine may be one of the most complex components in your vehicle, the driveshaft has an equally important job. The driveshaft transmits the power of the engine to the wheels, turning the wheels and making the vehicle move. Driveshaft torque refers to the force associated with rotational motion. Drive shafts must be able to withstand extreme conditions or they may break. Driveshafts are not designed to bend, so understanding how they work is critical to the proper functioning of the vehicle.

The drive shaft includes many components. The CV connector is one of them. This is the last stop before the wheels spin. CV joints are also known as “doughnut” joints. The CV joint helps balance the load on the driveshaft, the final stop between the engine and the final drive assembly. Finally, the axle is a single rotating shaft that transmits power from the final drive assembly to the wheels.

Different types of drive shafts have different numbers of joints. They transmit torque from the engine to the wheels and must accommodate differences in length and angle. The drive shaft of a front-wheel drive vehicle usually includes a connecting shaft, an inner constant velocity joint and an outer fixed joint. They also have anti-lock system rings and torsional dampers to help them run smoothly. This guide will help you understand the basics of driveshafts and keep your car in good shape.

The CV joint is the heart of the driveshaft, it enables the wheels of the car to move at a constant speed. The connector also helps transmit power efficiently. You can learn more about CV joint driveshafts by looking at the top 3 driveshaft questions

The U-joint on the intermediate shaft may be worn or damaged. Small deviations in these joints can cause slight vibrations and wobble. Over time, these vibrations can wear out drivetrain components, including U-joints and differential seals. Additional wear on the center support bearing is also expected. If your driveshaft is leaking oil, the next step is to check your transmission.

The drive shaft is an important part of the car. They transmit power from the engine to the transmission. They also connect the axles and CV joints. When these components are in good condition, they transmit power to the wheels. If you find them loose or stuck, it can cause the vehicle to bounce. To ensure proper torque transfer, your car needs to stay on the road. While rough roads are normal, bumps and bumps are common.

Common signs of damaged driveshafts

If your vehicle vibrates heavily underneath, you may be dealing with a faulty propshaft. This issue limits your overall control of the vehicle and cannot be ignored. If you hear this noise frequently, the problem may be the cause and should be diagnosed as soon as possible. Here are some common symptoms of a damaged driveshaft. If you experience this noise while driving, you should have your vehicle inspected by a mechanic.

A clanging sound can also be one of the signs of a damaged driveshaft. A ding may be a sign of a faulty U-joint or center bearing. This can also be a symptom of worn center bearings. To keep your vehicle safe and functioning properly, it is best to have your driveshaft inspected by a certified mechanic. This can prevent serious damage to your car.

A worn drive shaft can cause difficulty turning, which can be a major safety issue. Fortunately, there are many ways to tell if your driveshaft needs service. The first thing you can do is check the u-joint itself. If it moves too much or too little in any direction, it probably means your driveshaft is faulty. Also, rust on the bearing cap seals may indicate a faulty drive shaft.

The next time your car rattles, it might be time for a mechanic to check it out. Whether your vehicle has a manual or automatic transmission, the driveshaft plays an important role in your vehicle’s performance. When one or both driveshafts fail, it can make the vehicle unsafe or impossible to drive. Therefore, you should have your car inspected by a mechanic as soon as possible to prevent further problems.

Your vehicle should also be regularly lubricated with grease and chain to prevent corrosion. This will prevent grease from escaping and causing dirt and grease to build up. Another common sign is a dirty driveshaft. Make sure your phone is free of debris and in good condition. Finally, make sure the driveshaft chain and cover are in place. In most cases, if you notice any of these common symptoms, your vehicle’s driveshaft should be replaced.

Other signs of a damaged driveshaft include uneven wheel rotation, difficulty turning the car, and increased drag when trying to turn. A worn U-joint also inhibits the ability of the steering wheel to turn, making it more difficult to turn. Another sign of a faulty driveshaft is the shuddering noise the car makes when accelerating. Vehicles with damaged driveshafts should be inspected as soon as possible to avoid costly repairs.

editor by CX 2023-05-15

China Pto Shaft Drive Shaft Cardan Metal Steel Tractor Worm Gear Drive Shaft Agricultural Machinery drive shaft assembly parts

Solution Description

Pto Shaft Generate Shaft Cardan Metal Steel Tractor Worm Gear Travel Shaft Agricultural Equipment

|

/ Piece | |

100 Pieces (Min. Order) |

###

| Material: | Carbon Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Flexible Shaft |

| Journal Diameter Dimensional Accuracy: | IT6-IT9 |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Real Axis |

###

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) |

|---|

|

/ Piece | |

100 Pieces (Min. Order) |

###

| Material: | Carbon Steel |

|---|---|

| Load: | Drive Shaft |

| Stiffness & Flexibility: | Flexible Shaft |

| Journal Diameter Dimensional Accuracy: | IT6-IT9 |

| Axis Shape: | Straight Shaft |

| Shaft Shape: | Real Axis |

###

| Samples: |

US$ 9999/Piece

1 Piece(Min.Order) |

|---|

How to tell if your driveshaft needs replacing

What is the cause of the unbalanced drive shaft? Unstable U-joint? Your car may make clicking noises while driving. If you can hear it from both sides, it might be time to hand it over to the mechanic. If you’re not sure, read on to learn more. Fortunately, there are many ways to tell if your driveshaft needs replacing.

unbalanced

An unbalanced driveshaft can be the source of strange noises and vibrations in your vehicle. To fix this problem, you should contact a professional. You can try a number of things to fix it, including welding and adjusting the weight. The following are the most common methods. In addition to the methods above, you can use standardized weights to balance the driveshaft. These standardized weights are attached to the shaft by welders.

An unbalanced drive shaft typically produces lateral vibrations per revolution. This type of vibration is usually caused by a damaged shaft, missing counterweights, or a foreign object stuck on the drive shaft. On the other hand, torsional vibrations occur twice per revolution, and they are caused by shaft phase shifts. Finally, critical speed vibration occurs when the RPM of the drive shaft exceeds its rated capacity. If you suspect a driveshaft problem, check the following:

Manually adjusting the imbalance of a drive shaft is not the easiest task. To avoid the difficulty of manual balancing, you can choose to use standardized weights. These weights are fixed on the outer circumference of the drive shaft. The operator can manually position the weight on the shaft with special tools, or use a robot. However, manual balancers have many disadvantages.

unstable

When the angular velocity of the output shaft is not constant, it is unstable. The angular velocity of the output shaft is 0.004 at ph = 29.5 and 1.9 at t = 1.9. The angular velocity of the intermediate shaft is not a problem. But when it’s unstable, the torque applied to it is too much for the machine. It might be a good idea to check the tension on the shaft.

An unstable drive shaft can cause a lot of noise and mechanical vibration. It can lead to premature shaft fatigue failure. CZPT studies the effect of shaft vibration on the rotor bearing system. They investigated the effect of flex coupling misalignment on the vibration of the rotor bearing system. They assume that the vibrational response has two components: x and y. However, this approach has limited application in many situations.

Experimental results show that the presence of cracks in the output shaft may mask the unbalanced excitation characteristics. For example, the presence of superharmonic peaks on the spectrum is characteristic of cracks. The presence of cracks in the output shaft masks unbalanced excitation characteristics that cannot be detected in the transient response of the input shaft. Figure 8 shows that the frequency of the rotor increases at critical speed and decreases as the shaft passes the natural frequency.

Unreliable

If you’re having trouble driving your car, chances are you’ve run into an unreliable driveshaft. This type of drivetrain can cause the wheels to stick or not turn at all, and also limit the overall control of the car. Whatever the reason, these issues should be resolved as soon as possible. Here are some symptoms to look for when diagnosing a driveshaft fault. Let’s take a closer look.

The first symptom you may notice is an unreliable drive shaft. You may feel vibrations, or hear noises under the vehicle. Depending on the cause, it could be a broken joint or a broken shaft. The good news is that driveshaft repairs are generally relatively inexpensive and take less time than a complete drivetrain replacement. If you’re not sure what to do, CZPT has a guide to replacing the U-connector.

One of the most common signs of an unreliable driveshaft is clanging and vibration. These sounds can be caused by worn bushings, loose U-joints, or damaged center bearings. This can cause severe vibration and noise. You can also feel these vibrations through the steering wheel or the floor. An unreliable driveshaft is a symptom of a bigger problem.

Unreliable U-joints

A car with an unreliable U-joint on the drive shaft can be dangerous. A bad u-joint can prevent the vehicle from driving properly and may even cause you trouble. Unreliable u-joints are cheap to replace and you should try getting parts from quality manufacturers. Unreliable U-joints can cause the car to vibrate in the chassis or gear lever. This is a sure sign that your car has been neglected in maintenance.

Replacing a U-joint is not a complicated task, but it requires special tools and a lot of elbow grease. If you don’t have the right tools, or you’re unfamiliar with mechanical terminology, it’s best to seek the help of a mechanic. A professional mechanic will be able to accurately assess the problem and propose an appropriate solution. But if you don’t feel confident enough, you can replace your own U-connector by following a few simple steps.

To ensure the vehicle’s driveshaft is not damaged, check the U-joint for wear and lubrication. If the U-joint is worn, the metal parts are likely to rub against each other, causing wear. The sooner a problem is diagnosed, the faster it can be resolved. Also, the longer you wait, the more you lose on repairs.

damaged drive shaft

The driveshaft is the part of the vehicle that connects the wheels. If the driveshaft is damaged, the wheels may stop turning and the vehicle may slow down or stop moving completely. It bears the weight of the car itself as well as the load on the road. So even a slight bend or break in the drive shaft can have dire consequences. Even a piece of loose metal can become a lethal missile if dropped from a vehicle.

If you hear a screeching noise or growl from your vehicle when shifting gears, your driveshaft may be damaged. When this happens, damage to the u-joint and excessive slack in the drive shaft can result. These conditions can further damage the drivetrain, including the front half. You should replace the driveshaft as soon as you notice any symptoms. After replacing the driveshaft, you can start looking for signs of wear.

A knocking sound is a sign of damage to the drive shaft. If you hear this sound while driving, it may be due to worn couplings, damaged propshaft bearings, or damaged U-joints. In some cases, the knocking noise can even be caused by a damaged U-joint. When this happens, you may need to replace the entire driveshaft, requiring a new one.

Maintenance fees

The cost of repairing a driveshaft varies widely, depending on the type and cause of the problem. A new driveshaft costs between $300 and $1,300, including labor. Repairing a damaged driveshaft can cost anywhere from $200 to $300, depending on the time required and the type of parts required. Symptoms of a damaged driveshaft include unresponsiveness, vibration, chassis noise and a stationary car.

The first thing to consider when estimating the cost of repairing a driveshaft is the type of vehicle you have. Some vehicles have more than one, and the parts used to make them may not be compatible with other cars. Even if the same car has two driveshafts, the damaged ones will cost more. Fortunately, many auto repair shops offer free quotes to repair damaged driveshafts, but be aware that such work can be complicated and expensive.

editor by CX 2023-04-04

China Custom Made Drive Shaft Worm Gear/ Pinion/Helical Gear/ Spline/ Motor/ Transmission/ Gear Shift/ Screw/ Hollow/ Steel/Ground Shaft drive shaft bearing

Merchandise Description

HangZhou CZPT Precision Industry Co.,Ltd

The firm has owned IS0 9001 (Intercontinental Good quality Administration) technique certification, ISO14001 (International Environmental Administration) method certification, IATF16949 (International Automotive Activity Power) program certification and EN15085-2 (Railway programs-Welding of railway cars and elements) method certification. We have an knowledgeable administration crew and a group of high-high quality abilities.

Our positive aspects are as below.

- Main Value: Integrity + Top quality

- Rich Experience: Since the year of 2001

- Technical Engineer: 36 Staffs

- High quality Engineer: 18 Staffs

- Firm Certificate: ISO 9001, ISO14001, ITAF 16949, EN 15085-two

- Sturdy Ability: Up to 100k items per day

| Factory Description and Provider Material | ||||||||||||||||||||||

| Production LINE: | Metallic stamping, Laser cutting, Sheet metallic, Welding, Spraying, Electrophoresis, Assembly. | |||||||||||||||||||||

| Content: | Carbon steel, Stainless metal, Aluminum, Copper, Brass, Bronze, Custom-made. | |||||||||||||||||||||

| Procedures: | Blanking, Punching, Bending, Reducing, Milling, Dilling, Tapping, Riveting, Welding, Assembling, Packing. | |||||||||||||||||||||

| TOLERANCE: | +/- .01mm | |||||||||||||||||||||

| End: | Powder, Spraying, Sand Blasting, Electroplating, Electrophoresis, Anodizing, Passivating, Tailored. | |||||||||||||||||||||

| Color: | Natural, Conversonial, Silver, Grey, Black, White, Pink, Blue, Inexperienced, Yellow, Matte, Glossy, Tailored. | |||||||||||||||||||||

| System CERTIFICATION: | ISO 9001, ISO 14001, ITAF 16949, EN 15085-2. | |||||||||||||||||||||

| Application: | Auto, Interaction, Electrical, Electronics, Rail transit, Tools manufacturing and so forth. | |||||||||||||||||||||

| MOQ: | one,000 Pcs ~ 5,000 Pcs | |||||||||||||||||||||

| MOULD Value: | five hundred USD ~ 5,000 USD | |||||||||||||||||||||

| Device Price tag: | .05 USD ~ 5.00 USD | |||||||||||||||||||||

| PACKING: | Paper Bag, Plastic Bag, PE Bag, Carton Board, Carton Box, Plywood scenario, Wooden Scenario, Pallet. | |||||||||||||||||||||

| MPQ: | 50 Pcs ~ two hundred Pcs | |||||||||||||||||||||

| Lead TIME: | fifteen Operate Times ~ twenty five Perform Times | |||||||||||||||||||||

| TRADE Expression: | EXW, FOB, CFR, CIF, DDU, DDP. | |||||||||||||||||||||

| PAYMENT Strategy: | T/T, L/C, Western Union, Funds Gram, PayPal, Ali Pay. | |||||||||||||||||||||

Workshop Internal Look at

Program Certificate

Production Line View

Metalworking products are very crucial ingredient in industrial discipline, It is commonly recognized for its steady performance and inexpensive price tag.

Specially in the discipline of Car, Communication, Electrical, Electronics, IT, Tools Production, Rail Transit and Development etc.

We fully commited to offer our customers with exceptional products and cater to their demand from customers answers with reduced fees and highly effectiveness. Make sure you truly feel cost-free to make contact with us, we are looking forward to our even more cooperation. We handle each client sincerely and just take each and every project significantly.

| FAQ:

one. Why enterprise with CZPT Precision Co., Ltd? 2. Are the products offered for offering from your Solution Show Location? three. How to get your quotation? four. What is your production leadtime? 5. How to guarantee the products top quality? |

|

US $888-899 / Piece | |

100 Pieces (Min. Order) |

###

| Application: | Fastener, Auto and Motorcycle Accessory, Hardware Tool, Machinery Accessory |

|---|---|

| Standard: | GB, EN, API650, China GB Code, JIS Code, TEMA, ASME |

| Surface Treatment: | Powder Coated Anodizing Spray Paint Passivating |

| Production Type: | Mass Production |

| Machining Method: | CNC Machining Turning Milling Stamping Extrusion |

| Material: | Steel, Brass, Alloy, Copper, Aluminum, Iron |

###

| Samples: |

US$ 90/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Factory Description and Service Content | ||||||||||||||||||||||

| PRODUCTION LINE: | Metal stamping, Laser cutting, Sheet metal, Welding, Spraying, Electrophoresis, Assembly. | |||||||||||||||||||||

| MATERIAL: | Carbon steel, Stainless steel, Aluminum, Copper, Brass, Bronze, Customized. | |||||||||||||||||||||

| PROCEDURES: | Blanking, Punching, Bending, Cutting, Milling, Dilling, Tapping, Riveting, Welding, Assembling, Packing. | |||||||||||||||||||||

| TOLERANCE: | +/- 0.01mm | |||||||||||||||||||||

| FINISH: | Powder, Spraying, Sand Blasting, Electroplating, Electrophoresis, Anodizing, Passivating, Customized. | |||||||||||||||||||||

| COLOR: | Natural, Conversonial, Silver, Grey, Black, White, Red, Blue, Green, Yellow, Matte, Glossy, Customized. | |||||||||||||||||||||

| SYSTEM CERTIFICATION: | ISO 9001, ISO 14001, ITAF 16949, EN 15085-2. | |||||||||||||||||||||

| APPLICATION: | Automobile, Communication, Electrical, Electronics, Rail transit, Equipment manufacturing etc. | |||||||||||||||||||||

| MOQ: | 1,000 Pcs ~ 5,000 Pcs | |||||||||||||||||||||

| MOULD COST: | 500 USD ~ 5,000 USD | |||||||||||||||||||||

| UNIT PRICE: | 0.05 USD ~ 5.00 USD | |||||||||||||||||||||

| PACKING: | Paper Bag, Plastic Bag, PE Bag, Carton Board, Carton Box, Plywood case, Wooden Case, Pallet. | |||||||||||||||||||||

| MPQ: | 50 Pcs ~ 200 Pcs | |||||||||||||||||||||

| LEAD TIME: | 15 Work Days ~ 25 Work Days | |||||||||||||||||||||

| TRADE TERM: | EXW, FOB, CFR, CIF, DDU, DDP. | |||||||||||||||||||||

| PAYMENT METHOD: | T/T, L/C, Western Union, Money Gram, PayPal, Ali Pay. | |||||||||||||||||||||

###

| FAQ:

1. Why business with Hetai Precision Co., Ltd? 2. Are the products available for selling from your Product Display Area? 3. How to get your quotation? 4. What’s your production leadtime? 5. How to guarantee the products quality? |

|

US $888-899 / Piece | |

100 Pieces (Min. Order) |

###

| Application: | Fastener, Auto and Motorcycle Accessory, Hardware Tool, Machinery Accessory |

|---|---|

| Standard: | GB, EN, API650, China GB Code, JIS Code, TEMA, ASME |

| Surface Treatment: | Powder Coated Anodizing Spray Paint Passivating |

| Production Type: | Mass Production |

| Machining Method: | CNC Machining Turning Milling Stamping Extrusion |

| Material: | Steel, Brass, Alloy, Copper, Aluminum, Iron |

###

| Samples: |

US$ 90/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

###

| Factory Description and Service Content | ||||||||||||||||||||||

| PRODUCTION LINE: | Metal stamping, Laser cutting, Sheet metal, Welding, Spraying, Electrophoresis, Assembly. | |||||||||||||||||||||

| MATERIAL: | Carbon steel, Stainless steel, Aluminum, Copper, Brass, Bronze, Customized. | |||||||||||||||||||||

| PROCEDURES: | Blanking, Punching, Bending, Cutting, Milling, Dilling, Tapping, Riveting, Welding, Assembling, Packing. | |||||||||||||||||||||

| TOLERANCE: | +/- 0.01mm | |||||||||||||||||||||

| FINISH: | Powder, Spraying, Sand Blasting, Electroplating, Electrophoresis, Anodizing, Passivating, Customized. | |||||||||||||||||||||

| COLOR: | Natural, Conversonial, Silver, Grey, Black, White, Red, Blue, Green, Yellow, Matte, Glossy, Customized. | |||||||||||||||||||||

| SYSTEM CERTIFICATION: | ISO 9001, ISO 14001, ITAF 16949, EN 15085-2. | |||||||||||||||||||||

| APPLICATION: | Automobile, Communication, Electrical, Electronics, Rail transit, Equipment manufacturing etc. | |||||||||||||||||||||

| MOQ: | 1,000 Pcs ~ 5,000 Pcs | |||||||||||||||||||||

| MOULD COST: | 500 USD ~ 5,000 USD | |||||||||||||||||||||

| UNIT PRICE: | 0.05 USD ~ 5.00 USD | |||||||||||||||||||||

| PACKING: | Paper Bag, Plastic Bag, PE Bag, Carton Board, Carton Box, Plywood case, Wooden Case, Pallet. | |||||||||||||||||||||

| MPQ: | 50 Pcs ~ 200 Pcs | |||||||||||||||||||||

| LEAD TIME: | 15 Work Days ~ 25 Work Days | |||||||||||||||||||||

| TRADE TERM: | EXW, FOB, CFR, CIF, DDU, DDP. | |||||||||||||||||||||

| PAYMENT METHOD: | T/T, L/C, Western Union, Money Gram, PayPal, Ali Pay. | |||||||||||||||||||||

###

| FAQ:

1. Why business with Hetai Precision Co., Ltd? 2. Are the products available for selling from your Product Display Area? 3. How to get your quotation? 4. What’s your production leadtime? 5. How to guarantee the products quality? |

Guide to Drive Shafts and U-Joints

If you’re concerned about the performance of your car’s driveshaft, you’re not alone. Many car owners are unaware of the warning signs of a failed driveshaft, but knowing what to look for can help you avoid costly repairs. Here is a brief guide on drive shafts, U-joints and maintenance intervals. Listed below are key points to consider before replacing a vehicle driveshaft.

Symptoms of Driveshaft Failure

Identifying a faulty driveshaft is easy if you’ve ever heard a strange noise from under your car. These sounds are caused by worn U-joints and bearings supporting the drive shaft. When they fail, the drive shafts stop rotating properly, creating a clanking or squeaking sound. When this happens, you may hear noise from the side of the steering wheel or floor.

In addition to noise, a faulty driveshaft can cause your car to swerve in tight corners. It can also lead to suspended bindings that limit overall control. Therefore, you should have these symptoms checked by a mechanic as soon as you notice them. If you notice any of the symptoms above, your next step should be to tow your vehicle to a mechanic. To avoid extra trouble, make sure you’ve taken precautions by checking your car’s oil level.

In addition to these symptoms, you should also look for any noise from the drive shaft. The first thing to look for is the squeak. This was caused by severe damage to the U-joint attached to the drive shaft. In addition to noise, you should also look for rust on the bearing cap seals. In extreme cases, your car can even shudder when accelerating.

Vibration while driving can be an early warning sign of a driveshaft failure. Vibration can be due to worn bushings, stuck sliding yokes, or even springs or bent yokes. Excessive torque can be caused by a worn center bearing or a damaged U-joint. The vehicle may make unusual noises in the chassis system.

If you notice these signs, it’s time to take your car to a mechanic. You should check regularly, especially heavy vehicles. If you’re not sure what’s causing the noise, check your car’s transmission, engine, and rear differential. If you suspect that a driveshaft needs to be replaced, a certified mechanic can replace the driveshaft in your car.

Drive shaft type

Driveshafts are used in many different types of vehicles. These include four-wheel drive, front-engine rear-wheel drive, motorcycles and boats. Each type of drive shaft has its own purpose. Below is an overview of the three most common types of drive shafts:

The driveshaft is a circular, elongated shaft that transmits torque from the engine to the wheels. Drive shafts often contain many joints to compensate for changes in length or angle. Some drive shafts also include connecting shafts and internal constant velocity joints. Some also include torsional dampers, spline joints, and even prismatic joints. The most important thing about the driveshaft is that it plays a vital role in transmitting torque from the engine to the wheels.

The drive shaft needs to be both light and strong to move torque. While steel is the most commonly used material for automotive driveshafts, other materials such as aluminum, composites, and carbon fiber are also commonly used. It all depends on the purpose and size of the vehicle. Precision Manufacturing is a good source for OEM products and OEM driveshafts. So when you’re looking for a new driveshaft, keep these factors in mind when buying.

Cardan joints are another common drive shaft. A universal joint, also known as a U-joint, is a flexible coupling that allows one shaft to drive the other at an angle. This type of drive shaft allows power to be transmitted while the angle of the other shaft is constantly changing. While a gimbal is a good option, it’s not a perfect solution for all applications.

CZPT, Inc. has state-of-the-art machinery to service all types of drive shafts, from small cars to race cars. They serve a variety of needs, including racing, industry and agriculture. Whether you need a new drive shaft or a simple adjustment, the staff at CZPT can meet all your needs. You’ll be back on the road soon!

U-joint

If your car yoke or u-joint shows signs of wear, it’s time to replace them. The easiest way to replace them is to follow the steps below. Use a large flathead screwdriver to test. If you feel any movement, the U-joint is faulty. Also, inspect the bearing caps for damage or rust. If you can’t find the u-joint wrench, try checking with a flashlight.

When inspecting U-joints, make sure they are properly lubricated and lubricated. If the joint is dry or poorly lubricated, it can quickly fail and cause your car to squeak while driving. Another sign that a joint is about to fail is a sudden, excessive whine. Check your u-joints every year or so to make sure they are in proper working order.

Whether your u-joint is sealed or lubricated will depend on the make and model of your vehicle. When your vehicle is off-road, you need to install lubricable U-joints for durability and longevity. A new driveshaft or derailleur will cost more than a U-joint. Also, if you don’t have a good understanding of how to replace them, you may need to do some transmission work on your vehicle.

When replacing the U-joint on the drive shaft, be sure to choose an OEM replacement whenever possible. While you can easily repair or replace the original head, if the u-joint is not lubricated, you may need to replace it. A damaged gimbal joint can cause problems with your car’s transmission or other critical components. Replacing your car’s U-joint early can ensure its long-term performance.

Another option is to use two CV joints on the drive shaft. Using multiple CV joints on the drive shaft helps you in situations where alignment is difficult or operating angles do not match. This type of driveshaft joint is more expensive and complex than a U-joint. The disadvantages of using multiple CV joints are additional length, weight, and reduced operating angle. There are many reasons to use a U-joint on a drive shaft.

maintenance interval

Checking U-joints and slip joints is a critical part of routine maintenance. Most vehicles are equipped with lube fittings on the driveshaft slip joint, which should be checked and lubricated at every oil change. CZPT technicians are well-versed in axles and can easily identify a bad U-joint based on the sound of acceleration or shifting. If not repaired properly, the drive shaft can fall off, requiring expensive repairs.

Oil filters and oil changes are other parts of a vehicle’s mechanical system. To prevent rust, the oil in these parts must be replaced. The same goes for transmission. Your vehicle’s driveshaft should be inspected at least every 60,000 miles. The vehicle’s transmission and clutch should also be checked for wear. Other components that should be checked include PCV valves, oil lines and connections, spark plugs, tire bearings, steering gearboxes and brakes.

If your vehicle has a manual transmission, it is best to have it serviced by CZPT’s East Lexington experts. These services should be performed every two to four years or every 24,000 miles. For best results, refer to the owner’s manual for recommended maintenance intervals. CZPT technicians are experienced in axles and differentials. Regular maintenance of your drivetrain will keep it in good working order.

editor by czh 2023-01-23

China factory Factory Direct Sales RV Series Worm Gear Box Nrv Worm Gearbox With Input Shaft with Free Design Custom

Products Description Features and application scenarios of RV series worm gear reducerRV reducer is based on the parameters of cylindrical worm gear and worm gear in line with the national standard GB10085-88, absorbs the most advanced technology at home and abroad, and has a unique and novel “square box” shape structure. It has the following advantages:1. The mechanical structure is compact, the volume is light and the shape is small and efficient;2. Good heat exchange performance and fast heat dissipation;3. Easy to install, flexible and light, superior performance, easy to maintain and repair;4. Smooth operation, low noise and durable;5. Strong applicability, high safety and reliability.RV series worm gear reducers have been widely used in mechanical reducers of process equipment in metallurgy, mining, chemical industry, food, 2571 CNC machining off-center spindle top precision manufacturer machining prototype stainless steel crusher eccentric shaft beverage, textile, packaging, environmental protection and other industries and fields. It is well received by users and is the best choice for modern industrial equipment to achieve large torque, large speed ratio, low noise and high stability of mechanical deceleration transmission control devices. Product Paramenters Product NameNRV Worm GearboxColorBlue/Silver Or On Customer RequestRatio5-100Model 25 30 40 50 63 75 80 90 110 130 150Material of HousingCasting Iron/Aluminum alloyBrandBeiji or customizedOutput FormSolid shaft/hollow shaftUsages:Metallurgical industry, mining industry, chemical industry, food industry, beverage industry, textile industry, packagingindustry, environmental protection industry Company Profile About US HangZhou Jinhongda Transmission Equipment Co., Ltd is a modern enterprise integrating industry and trade. Our sales department is located in HangZhou baoan district. A total of 15 employees are responsible for domestic and international operations.In China, We has established the Pearl River Delta as the center to cover the national sales network. Our products are also exported to the United States, Germany, France, Holland, CZPT Hydraulic motor A6VM spare parts swash plate cylinder block pistons set plate drive shaft center pin valve plate Spain, Korea, Japan, Saudi Arabia, Thailand and other countries and regions. Our factory is located in HangZhou, ZheJiang , covering an area of 10,000 square meters.Our factory has dozens of professional CNC machining equipment and several precision measuring equipment and more than 100 professionals.The company has been adhering to scientific and technological innovation, research and introduction of advanced technology, and constantly develop new products to meet the market demand.The monthly production capacity reaches 10,000 units. Our main products are BeiJi precision planetary reducer, R/ S/F/K series helical gear reducer, RV reducer, small gear reducer, medium gear reducer, cast iron worm gear reducer, CAM splitter and other transmission equipment.We can also provide OEM products and special purpose products. We have a strong technical capability, has obtained ISO 9001:2008 quality management system certification and manufacturing in strict accordance with the requirements. Our products have been widely used in petroleum, Hot selling RC Crawler Car parts 30mm Metal Copper Drive Shaft chemical equipment, plastic machinery, rubber machinery, food machinery, packaging machinery, three-dimensional parking garage and assembly line and other machinery and equipment fields, won the majority of users’ satisfaction and praise.If you have needs, please contact us. Certifications Why Choose Us Packing and Shipping Product application scenarios FAQ Q: Are you a trading company or a manufacturer ?A: We are a speed reducer gearbox manufacturer in ZheJiang Province, China. Our company owns the ability ofmanufacturing,processing, designing and R&D. Q:What information should i tell you to confirm the worm gearbox?A:Model/Size,B:Ratio and output torque, C:Power and flange type,D:Shaft Direction,E:Housing color,F:Order quantity. Q: Can you customize according to our requirements?A: Yes, CZPT custom 22mm 3v 6v 12v 24v micro planetary plastic gearbox dc motor for toy car we can design non-standard products according to customers’ drawings and samples. Q:What is the payment term?A:T/T and Paypal is used more,please contact us for details Q: How long is the delivery date?A: 10 – 20 business days.

An Overview of Worm Shafts and Gears

This article provides an overview of worm shafts and gears, including the type of toothing and deflection they experience. Other topics covered include the use of aluminum versus bronze worm shafts, calculating worm shaft deflection and lubrication. A thorough understanding of these issues will help you to design better gearboxes and other worm gear mechanisms. For further information, please visit the related websites. We also hope that you will find this article informative.

Double throat worm gears

The pitch diameter of a worm and the pitch of its worm wheel must be equal. The two types of worm gears have the same pitch diameter, but the difference lies in their axial and circular pitches. The pitch diameter is the distance between the worm’s teeth along its axis and the pitch diameter of the larger gear. Worms are made with left-handed or right-handed threads. The lead of the worm is the distance a point on the thread travels during one revolution of the worm gear. The backlash measurement should be made in a few different places on the gear wheel, as a large amount of backlash implies tooth spacing.

A double-throat worm gear is designed for high-load applications. It provides the tightest connection between worm and gear. It is crucial to mount a worm gear assembly correctly. The keyway design requires several points of contact, which block shaft rotation and help transfer torque to the gear. After determining the location of the keyway, a hole is drilled into the hub, which is then screwed into the gear.

The dual-threaded design of worm gears allows them to withstand heavy loads without slipping or tearing out of the worm. A double-throat worm gear provides the tightest connection between worm and gear, and is therefore ideal for hoisting applications. The self-locking nature of the worm gear is another advantage. If the worm gears are designed well, they are excellent for reducing speeds, as they are self-locking.

When choosing a worm, the number of threads that a worm has is critical. Thread starts determine the reduction ratio of a pair, so the higher the threads, the greater the ratio. The same is true for the worm helix angles, which can be one, two, or three threads long. This varies between a single thread and a double-throat worm gear, and it is crucial to consider the helix angle when selecting a worm.

Double-throat worm gears differ in their profile from the actual gear. Double-throat worm gears are especially useful in applications where noise is an issue. In addition to their low noise, worm gears can absorb shock loads. A double-throat worm gear is also a popular choice for many different types of applications. These gears are also commonly used for hoisting equipment. Its tooth profile is different from that of the actual gear.

Bronze or aluminum worm shafts

When selecting a worm, a few things should be kept in mind. The material of the shaft should be either bronze or aluminum. The worm itself is the primary component, but there are also addendum gears that are available. The total number of teeth on both the worm and the addendum gear should be greater than forty. The axial pitch of the worm needs to match the circular pitch of the larger gear.

The most common material used for worm gears is bronze because of its desirable mechanical properties. Bronze is a broad term referring to various copper alloys, including copper-nickel and copper-aluminum. Bronze is most commonly created by alloying copper with tin and aluminum. In some cases, this combination creates brass, which is a similar metal to bronze. The latter is less expensive and suitable for light loads.

There are many benefits to bronze worm gears. They are strong and durable, and they offer excellent wear-resistance. In contrast to steel worms, bronze worm gears are quieter than their counterparts. They also require no lubrication and are corrosion-resistant. Bronze worms are popular with small, light-weight machines, as they are easy to maintain. You can read more about worm gears in CZPT’s CZPT.

Although bronze or aluminum worm shafts are the most common, both materials are equally suitable for a variety of applications. A bronze shaft is often called bronze but may actually be brass. Historically, worm gears were made of SAE 65 gear bronze. However, newer materials have been introduced. SAE 65 gear bronze (UNS C90700) remains the preferred material. For high-volume applications, the material savings can be considerable.

Both types of worms are essentially the same in size and shape, but the lead on the left and right tooth surfaces can vary. This allows for precise adjustment of the backlash on a worm without changing the center distance between the worm gear. The different sizes of worms also make them easier to manufacture and maintain. But if you want an especially small worm for an industrial application, you should consider bronze or aluminum.

Calculation of worm shaft deflection

The centre-line distance of a worm gear and the number of worm teeth play a crucial role in the deflection of the rotor. These parameters should be entered into the tool in the same units as the main calculation. The selected variant is then transferred to the main calculation. The deflection of the worm gear can be calculated from the angle at which the worm teeth shrink. The following calculation is helpful for designing a worm gear.

Worm gears are widely used in industrial applications due to their high transmittable torques and large gear ratios. Their hard/soft material combination makes them ideally suited for a wide range of applications. The worm shaft is typically made of case-hardened steel, and the worm wheel is fabricated from a copper-tin-bronze alloy. In most cases, the wheel is the area of contact with the gear. Worm gears also have a low deflection, as high shaft deflection can affect the transmission accuracy and increase wear.

Another method for determining worm shaft deflection is to use the tooth-dependent bending stiffness of a worm gear’s toothing. By calculating the stiffness of the individual sections of a worm shaft, the stiffness of the entire worm can be determined. The approximate tooth area is shown in figure 5.

Another way to calculate worm shaft deflection is by using the FEM method. The simulation tool uses an analytical model of the worm gear shaft to determine the deflection of the worm. It is based on a two-dimensional model, which is more suitable for simulation. Then, you need to input the worm gear’s pitch angle and the toothing to calculate the maximum deflection.

Lubrication of worm shafts

In order to protect the gears, worm drives require lubricants that offer excellent anti-wear protection, high oxidation resistance, and low friction. While mineral oil lubricants are widely used, synthetic base oils have better performance characteristics and lower operating temperatures. The Arrhenius Rate Rule states that chemical reactions double every ten degrees C. Synthetic lubricants are the best choice for these applications.

Synthetics and compounded mineral oils are the most popular lubricants for worm gears. These oils are formulated with mineral basestock and four to six percent synthetic fatty acid. Surface-active additives give compounded gear oils outstanding lubricity and prevent sliding wear. These oils are suited for high-speed applications, including worm gears. However, synthetic oil has the disadvantage of being incompatible with polycarbonate and some paints.

Synthetic lubricants are expensive, but they can increase worm gear efficiency and operating life. Synthetic lubricants typically fall into two categories: PAO synthetic oils and EP synthetic oils. The latter has a higher viscosity index and can be used at a range of temperatures. Synthetic lubricants often contain anti-wear additives and EP (anti-wear).

Worm gears are frequently mounted over or under the gearbox. The proper lubrication is essential to ensure the correct mounting and operation. Oftentimes, inadequate lubrication can cause the unit to fail sooner than expected. Because of this, a technician may not make a connection between the lack of lube and the failure of the unit. It is important to follow the manufacturer’s recommendations and use high-quality lubricant for your gearbox.

Worm drives reduce backlash by minimizing the play between gear teeth. Backlash can cause damage if unbalanced forces are introduced. Worm drives are lightweight and durable because they have minimal moving parts. In addition, worm drives are low-noise and vibration. In addition, their sliding motion scrapes away excess lubricant. The constant sliding action generates a high amount of heat, which is why superior lubrication is critical.

Oils with a high film strength and excellent adhesion are ideal for lubrication of worm gears. Some of these oils contain sulfur, which can etch a bronze gear. In order to avoid this, it is imperative to use a lubricant that has high film strength and prevents asperities from welding. The ideal lubricant for worm gears is one that provides excellent film strength and does not contain sulfur.

China manufacturer & factory supplier for Trapezoid in West Yorkshire United Kingdom screw worm gear screw jack SWL10 structure screw jack for lifting With high quality best price & service

ISO 9001:2000 certified. Stocking distributor of energy transmission products including roller & a number of strand roller chains. Items also incorporate brakes, generate parts, gears, torque limiters, U-joints, pulleys, sheaves, encoders, belt drives, clutches & motors are also offered.Top quality and credit history are the bases that make a corporation alive. a specialised supplier of a full assortment of chains, sprockets, gears, equipment racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Swift Information

- Relevant Industries:

-

Producing Plant

- Manufacturer Title:

-

OEM

- Item NO:

-

SYF

- Software:

-

Lifting Transpor

- Certification:

-

ISO 9001

- Housing Content:

-

Forged Iron HT200

- Output Type:

-

Shaft/Flange Output

Our goods is popular exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Center and South The united states, Thailand, Pakistan, Indonesia, a lot more than 60 nations around the world and areas.

- Lifting velocity:

-

.044-2.592m/min

- Worm velocity:

-

50-1800rpm

- Mounting Situation:

-

Foot Mounted. Flange Mounted

- Materials:

-

Cooper Wheel

Packaging & Shipping and delivery

-

Direct Time

: -

Quantity(Sets) one – 3 four – 5 >5 Est. Time(times) 5 10 To be negotiated

On the web Customization

Merchandise Description

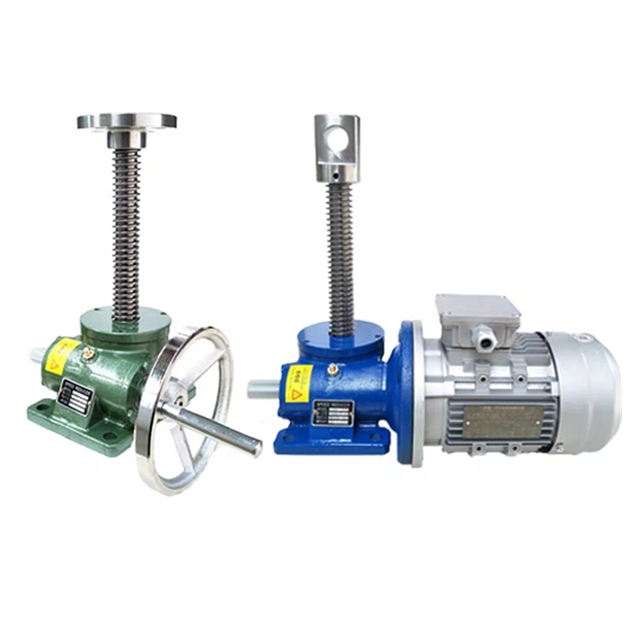

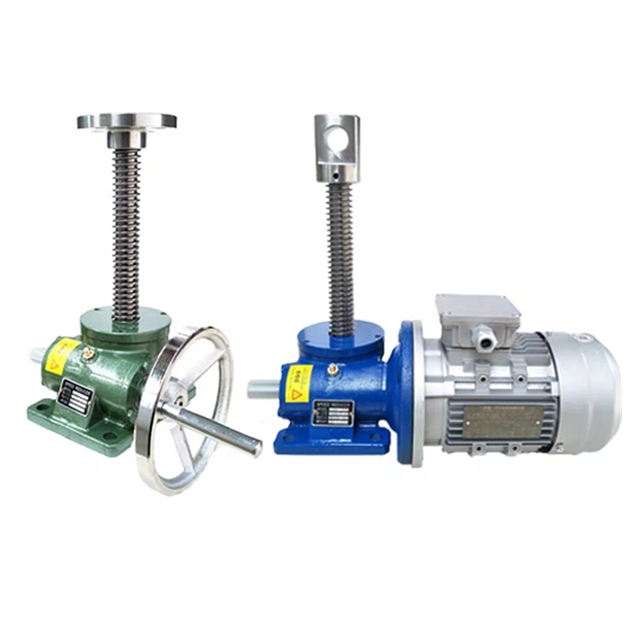

SWL Worm Equipment Screw Jack

SWL sequence worm wheel screw elevator is widely applied in idustries this kind of as equipment. meallurgy, development, and hydraulie products, and has many features this kind of as lfting and pushing and turming with the aid of acessories or modifying peak and placement.

This sequence worm screw elevator is one particular model of fundamental hoisting elements and has several functions of compact construction, modest volume, light-weight fat, vast travel sources, low sound, substantial reliabilit, and lengthy lifespan. In addition, they are straightforward to be mounted,adaptable in use and take pleasure in a number of capabilities.

This series, driven by motor or other electrical power or manually, can be utilised the two one and combined with other folks to precisely control the adjustment of peak of lfting or pushing by specific packages. For there are numerous structures and mounting situation, the lfting top can be adjusted to the customers rquirements.

|

SWL 2.5 M-1 A-Ⅱ-500 FZ |

||||||||||||||

|

SWL |

2.five |

M |

one |

A |

Ⅱ |

500 |

FZ |

|||||||

|

worm equipment screw jack |

bearing capability(25kN) |

Ratio Code |

structural form code |

construction |

assembly form |

Screw stroke(mm) |

Protection kind code |

|||||||

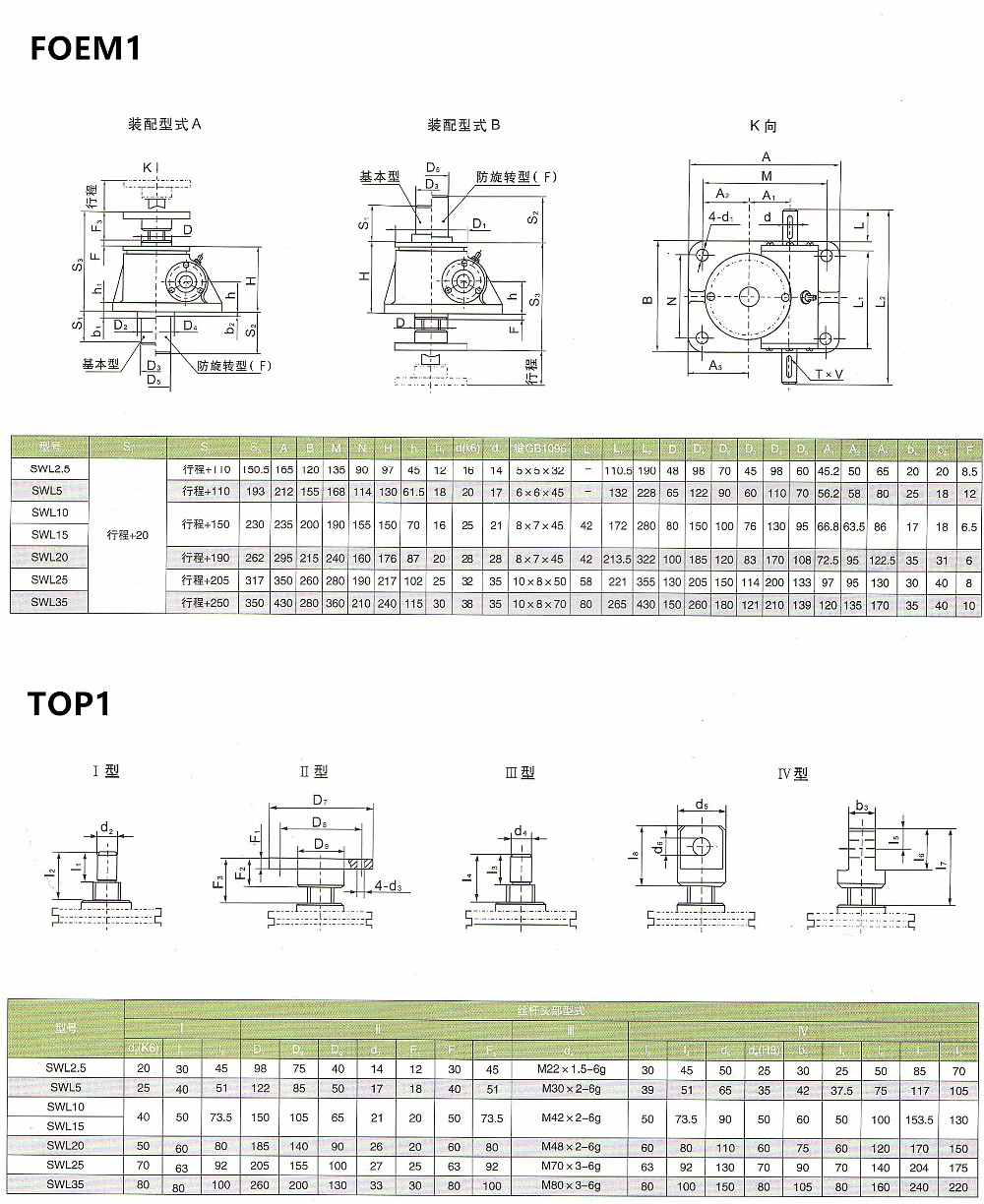

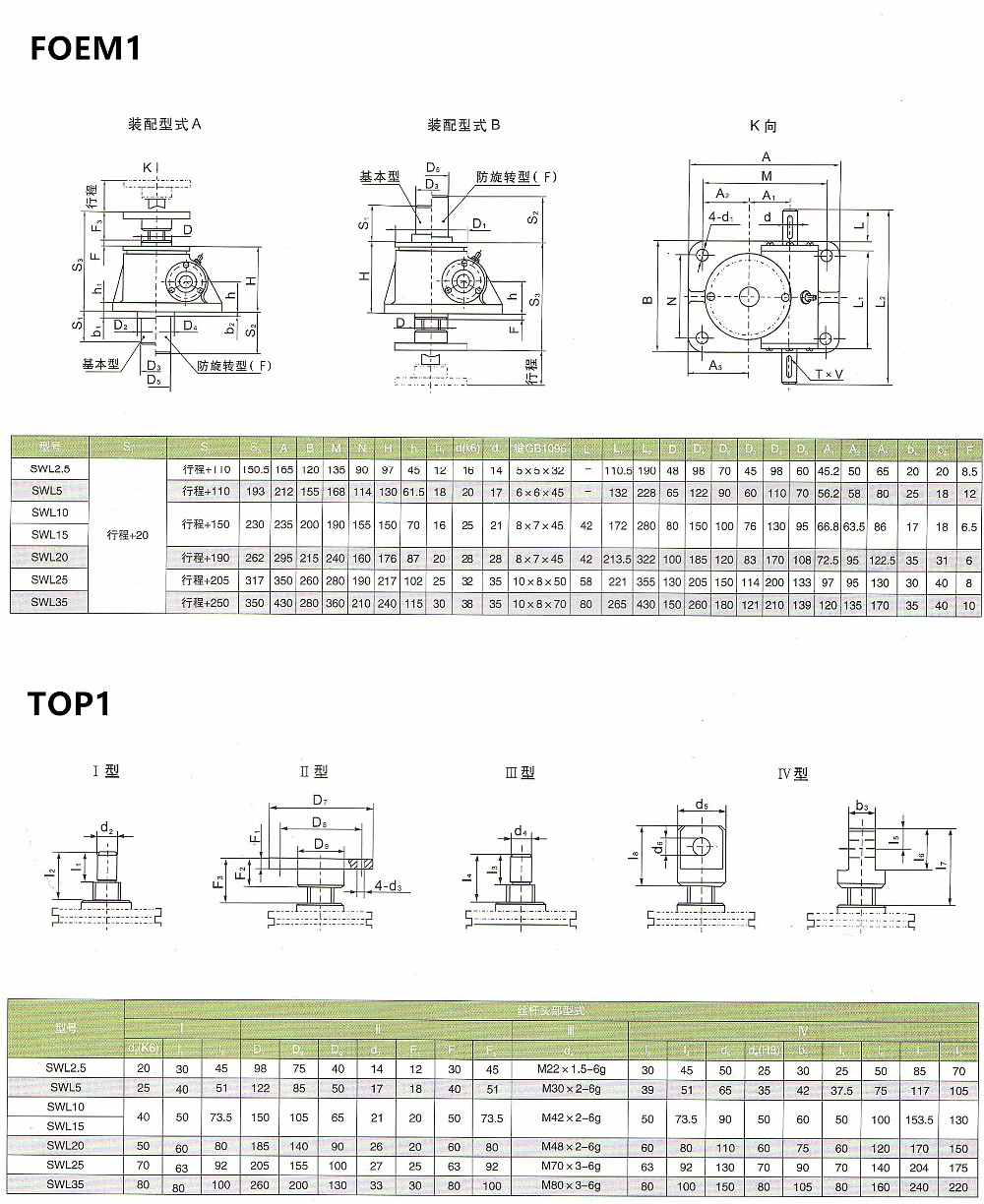

SWL Worm Equipment Screw Jack Mounting Proportions

Observe:

1. The allowable electricity is a parameter below the problem that the ambient temperature is 20℃ and the operating length price is twenty% for every hour.The whole efficiency is the parameter underneath the problem of grease lubrication.3. The allowable torque, power and speed are distinct when lifting diverse masses, and the electrical power of distinct beginning duration is different4. For the raise with double guide sleeve, the screw can bear lateral drive as nicely as axial pressure.The radial power that the worm shaft extension is allowed to bear is authorized to install gear, sprocket or pulley.6. Seek the advice of the maker for the above information.7. It can be self-locked at relaxation.

SWL Worm Equipment Screw Jack Features:

one. Compact structure, modest quantity and convenient set up

2. High dependability and lengthy existence.

three. It has a lot of capabilities, such as lifting, descending, pushing and flipping with auxiliary elements.

4. It can be utilized alone or in blend.

five.The electrical power supply is substantial. It can be driven immediately by motor or other electricity or manually.

ninety four Copper Worm Wheel

ninety four Copper Worm Wheel with Large Put on Resistance.

Large Good quality SHELL Materials

The box physique which is cleaned by professional screening and washing equipment to make sure that the interior cavity of the box physique is cleanerTECHNOLOGY Leader IN THE DRIVES SECTOR Managing motion with the maximum precision – this challenge has been driving WITTENSTEIN for more than 30 several years now. This great dedication has assisted us turn into an undisputed worldwide technology and good quality leader. with no iron filings.

Our Organization

HANGZHOU Ever-Energy Team, One OF THE Greatest GEARBOX Manufacturing unit IN CHINA, ELECTROMECHANICAL Equipment Source STATION

Our firm is situated in the town of HangZhou, ZheJiang Province of China.

We deal with the products of power transmission, our strains largely include collection items in pace reducers, gearboxes , associated electricial motors and other power transmission components. Based on the functional functions, our products can be utilized in numerous fields: macPTO Adapters To keep away from possible connectivity troubles, you may possibly want to take into account a PTO Adapter for your tractor. The PTO adapter extends the relationship to the put into action, offering extra place for the PTO shaft to change with out touching the Arm Weldment or other components of your tractor or the put into action.hines of squander h2o therapy, dredgers, chemical industry, cranes, metallic operating mills, conveyors, paper business, cement business, cableways and so on.With the excellent quality and realistic cost , our goods enjoy a great status from buyers and the peers all over the entire world.

In addition, the R&D expense are yearly rising for the objective of better assembly the new needs of our buyers and adapting the new inclination of the business.

Dependent on the principles of honestly running and mutual reward, We sincerely appear ahead to cooperating with you.

Application region

SWL sequence worm and screw elevators are widely utilized in equipment, metallurgy, building, drinking water conservancy equipment and other industries. They have the capabilities of lifting, descending, advancing by auxiliary parts, turning more than and other peak adjustment capabilities.

Packing&Transportion

PACKING AND TRANSPORTION

●Packaging: In buy to guarantee the integrity of solution look, we will pick cartons, picket pallets and wood pallets in accordance to client wants.

●Delivery time: Each reducer is produced and examined in accordance with rigorous and fixed processes to ensure that the top quality is appropriate before leaving the factory and shipping on time.

●Transportation mode: We will choose the most appropriate manner of transportation for our consumers in accordance to the weight and dimensions of the products. We can also pick the manner of transportation in accordance to the demands of our clients.

●Receiving and following-income service: Soon after receiving the goods, remember to examine whether they are in good issue. We will supply clients with best soon after-sales service.

FAQ

Q1: Are you a buying and selling company or a producer ?

A: We are a maker in ZheJiang Province, China. Our firm owns the capability of manufacturing, processing,developing and R&D. We welcome your visit.

Q2: How we pick versions and technical specs?

A: In accordance to the certain details of the demands from the element of enquiry, we will suggest the products’ versions on synthesizing the variables of area of items usage, electricity, torque arm and ratio…

Q3: How is your price tag? Can you offer any price reduction?

A: Our rates are often competitive. If the consumer can location a huge get, we absolutely will allow price cut.

This fall: How extended need to I hold out for the opinions right after I send the enquiry?

A4: We will reply the enquiries with out any delay, twelve hours at most.

Q5: What is your item guarantee period?

A: We have the certifications of ISO99001,CE, SGS.

Q6: What industries are your gearboxes becoming employed?

A: Our gearboxes are widely applied to metallurgical equipment, mining products, automation tools, meals machinery, packaging products, tobacco equipment and so on.

Double Custom made in China – replacement parts – in Abomey-Calavi Benin Worm Gear Reducer with Output Shaft with top quality

We – EPG Team the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears manufacturing facility in China with 5 different branches. For a lot more details: Cell/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828

RV collection Worm Gearbox

1. Solution Characteristics

Effective and safe running.

Compact structure and tiny volume conserve mounting space.

Large load ability and overload features give secure transmission with reduced vibration and minimal noise.

Tiny hole composition of gearbox can make this reducer routine maintenance free of charge and helps prevent lubricant from leaking.

Different linking structures for energy input and torque output allows for distinct mounting strategies.

Low noise and stably working, to adapt long phrase work problem in horrible atmosphere.

Light bodyweight and large mechanical toughness.

Motor mounting, shaft mounting and flange mounting.

two. RV sequence are extensively used, it is an excellent decision for contemporary industrial products to comprehend transmission and handle at massive speed lowering ratio.

| Input Electrical power | 0.06-7.5kW |

| Ratio | 5-one hundred |

| Output Torque | 0.06-1179N. m |

Software:

Ceramic Market

Glass Industry

Foodstuff Industry

Metallurgy Business

Beer& Consume Sector

Printing and dyeing Business

Textile Industry

Warehouse Logoistics Industry

Wood functioning Equipment

environmental defense gear Market

Leather Industry

Pharmacy Market

4.Our Providers

four.1.We give 12 months Guarantee.

4.2. We have thousands of gearbox reducers. From Input Electrical power .06KW to 200KW, Ratio 1.3-289.74, Output speed -1095rpm and Output torque 1.4-62800Nm…They can meet your all distinct requirements for distinct industries.

four.3. We offer E-catalog or Paper catalog,so you can choose the model very easily according to your requirements

4.4.You are welcome to check out our manufacturing unit to verify our items,we can assist you to ebook the ho tel: +86~thirteen 0571 88828 or ticket

5.Business Details

Firm Profile

ZheJiang Starshine Travel Co.,Ltd,the predecessor was a state-owned navy mould business, was recognized in 1965. Starshine specializes in the total power transmission answer for higher-finish gear producing industries dependent on the goal of “Platform Item, Application Design and Specialist Support”.

Starshine have a strong technical pressure with more than 350 workers at present, which includes in excess of 30 engineering specialists, 30 top quality inspectors, covering an location of 80000 sq. meters and varieties of superior processing equipment and tests equipments. We have a good basis for the business software advancement and services of substantial-stop speed reducers & variators owning to the provincial engineering technology study middle,the lab of gear speed reducers, and the foundation of contemporary R&D.

Our principal goods are R/S/K/F series helical geared motor, S EPT collection planetary gearboxes, SNKG collection bevel-helical gearmotor, NCJ sequence gear motor, RV series worm gearboxes, JWB-X series velocity variators, B/JXJ collection cycloidal gearboxes, XGK collection helical-hypoid Gearboxes, which commonly utilized in ceramic market, glass market, woodworking equipment , high voltage swap, foods & beverage, packaging & printing, Storage & logistics, hoisting & transportation facilities…etc , and Starshine technically give the professional solution & service for the medium and higher-conclude consumers, and our gearboxes are greatest-offering in domestic, and even in abroad , such as in Europe, North America, South The usa, Center East, South Asia, Southea EPT Asia, Africa…etc.

In the potential , Starshine will maintain the creed of “serving customer, diligence & simplicity, self-criticism, innovation, honesty, teamwork”, and the notion of “top quality produces benefit” to emphasis on the customers’ demands and provide them the aggressive transmission solution and produce worth for them constantly, and make a high-conclude products manufacturing business and produce a preferred manufacturer of changing import goods and upgrading repeatedly for the end consumers.

Amongst Dynamic and Static, Straightforward is Amazing, let us go ahead hand in hand and make a brilliant long term!

Our factory

one. three hundred sets sophisticated processing machines

2. “6S”Standardized Administration

Our Team

Technological Group

Sales Team

Exibition Demonstrate

2019 ASIA ceramics exhibition

2018 Entire world of Market Exhibition

Quality Assurance

Products one hundred% te EPT prior to delivery

Handed ISO 9001: 2015 Certificate.

Our support

one. We supply 12 months Guarantee.

2. We have hundreds of gearbox reducers. From Input Power .06KW to 200KW, Ratio 1.3-289.seventy four, Output speed -1095rpm and Output torque 1.4-62800Nm. They can satisfy your all various specifications for various industries.

3. 24 hrs on the web services.

4. Fa EPT delivry.

five. We provide E-catalog or Paper catalog,so you can decide on the model effortlessly according to your requirements

six. Welcome you come to our manufacturing unit to examine our items, we can support you to e-book the ho tel: +86~13 0571 88828 or ticket.

FAQ

Q:Are you a trading company or company?

A: We are producer.

Q:Exactly where do you base?

A: We are in Xihu (We EPT Lake) Dis. district, HangZhou, China.

Q:What types of gearbox can you create for us?

A: R/S/K/F collection helical geared motor, S EPT collection planetary gearboxes, SNKG series bevel-helical gearmotor, NCJ series gear motor, RV collection worm gearboxes, JWB-X series pace variators, B/JXJ collection cycloidal gearboxes, XGK series helical-hypoid Gearboxes

Q:What are the software of the gearbox?

A:Goods are extensively utilized in ceramic, glass, foodstuff, metallurgy, beer & drink, printing and dyeing, textile, petrochemical engineering, warehouse logistics, wooden-working device, environmental protection products, printing and packaging, pharmacy, and leather-based. Goods are sold in some international locations and areas, such as Europe, The usa, and Southea EPT Asia, and it possesses dozens of distributors and after-sale provider agents.

Q:What is the content you use?

A1: Aluminum Housing human body ( For the RV collection worm gearbox Dimension 30~90)

A2: EPT EPT iron(For the RV collection worm gearbox, Dimension a hundred and ten-a hundred and fifty, For the NCJ & F/R/S/K collection helical equipment reducer)

Any inquiry p EPT get in touch with:

Nicola Huang (Export income)

Internet site:

We – EPG Group the bigge EPT gearbox & motors , vee pulleys, timing pulleys, couplings and gears factory in China with 5 distinct branches. For a lot more particulars: Cellular/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778 0571 88828 The use of first tools manufacturer’s (OEM) part figures or emblems , e.g. CASE® and John Deere® are for reference needs only and for indicating merchandise use and compatibility. Our firm and the listed substitution elements contained herein are not sponsored, accredited, or created by the OEM.

Best China manufacturer & factory china in Jabalpur India manufacturer BMRV090 high efficiency small mini worm gear reducer for servo motor With high quality best price

The group is focused on producing all variety of standard roller chains and sprockets, gears & gearboxes, such as conveyor chain & sprockets , stainless steel chain, agricultural chain and has not just sold its products all over china, but also sold more than 65% products to oversees, including Europe, America, South-east Asia, and it also has set up storage logistics in places like Europe.

Overview

Quick Details

- Applicable Industries:

-

precision machinery

- Gearing Arrangement:

-

worm

- Output Torque:

-

351N.m

- Input Speed:

-

≤1500 rpm

- Output Speed:

-

*

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Product name:

-

worm gear reducer

- Ingress Protection:

-

IP65

- Ratio:

-

5~60

- Color:

-

gray /blue/black

- Heat treatment:

-

surface hardening

- Housing Material:

-

aluminum alloy

Supply Ability

- Supply Ability:

- 200000 Piece/Pieces per Month

Packaging & Delivery

- Port

- Ningbo/Shanghai/ China Port

-

Lead Time

: -

Quantity(Sets) 1 – 1000 >1000 Est. Time(days) 30 To be We get a lot of questions surrounding PTO shafts and how to attach them to your tractor. In today’s post, we’ll cover the basics of PTO, PTO Shafts, and PTO adapters for your tractor mounted implements. PTO stands for “Power Take-Off” and is the primary mechanism for providing power to an attachment or implement (such as a flail mower) via PTO shaft.By providing rotational energy through the driveshaft (or cardan shaft) a variety of tractor mounted implements can be operated by small and mid-sized tractors.negotiated

Online Customization

Ever-power Group Co., Ltd. is SPECIALIST IN MAKING ALL KINDS OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL GEAR SPEED REDUCERS, PARALLEL SHAFT HELICAL GEAR REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM GEAR REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, AUTO GEAREPG is willing to cooperate sincerely and develop commonly with friends!BOXES, PTO DRIVE SHAFTS, SPECIAL REDUCER & RELATED GEAR COMPONENTS AND OTHER RELATED PRODUCTS, SPROCKETS, HYDRAULIC SYSTEM, VACCUM PUMPS, FLUID COUPLING, GEAR RACKS, CHAINS, TIMING PULLEYS, UDL SPEED VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, GEAR PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS LOW BACKLASH WORM REDUCERS AND SO ON. FURTHERMORE, WE CAN PRODUCE CUSTOMIZED VARIATORS, GEARED MOTORS, ELECTRIC MOTORS AND OTHER HYDRAULIC PRODUCTS ACCORDING TO CUSTOMERS DRAWINGS.

HangZhou Ever-PowerMechanical & Electrical Co., Ltd. is a professional manufacturer ofgearbox and motors.The factory covers an area of 20,000 square meters, the building area of 30,000 square meters, the total number of staff is more than 200 .We have passed theISO9001:2015international quality management system standard certificate,CCCnational compulsory product certificate andCEcertificate . We have developed advanced management software such asERPto keep pace with international standard.In order to serve customers better the company actively cooperates with colleges and universities to develop new products and improve existing products .

|

Q1. Are you trading company or manufacturer? A. We are manufacturer Located in Taizhou City of East China. Q2. How is guarantee of the quality? With ISO9001:2015,CE,CCC certificated, Our inspectors sampled inspect and record material and semi-finished spare parts. And – 100% inspect finished spare parts before put in storage. – 100% inspect before assembly. – 100% inspect before packaging. Q3. What information shall we give before placing a purchase order? We can supply technical support and the drawing according to your requirement if you contact with me. Q4. What industries are your gearboxes being used? Our gearboxes are widely used in the areas of textile, food processing, beverage, chemical industry,escalator,automatic storage equipment, metallurgy, tabacco, environmental protection, logistics and etc. Q5. Do you have warranty service? Yes, the gearbox is free warranty within 1 years after delivery. |

||||||

china High Qualtiy manufacturer factory of Worm Gear Gearbox for Stepper Motor

specialize in electricity transmission items,pto shaft, agricultural gearboxes , CATV items, mechanical seal, hydraulic and Pheumatic, and advertising goods.

Overview

Fast Specifics

- Relevant Industries:

-

Producing Plant

- Application:

-

Mining

- Fat:

-

.4-45kg

- Rated Electricity:

-

.twelve-two hundred KW

- Shade:

-

Client Request

- Materials:

-

Cast Iron

- Certification:

-

ISO9001

- Mount Situation:

-

Foot Mounted. Flange Mounted

- Transport:

-

Convey

- MOQ:

-

1pcs

- Quality:

-

Higher Precision

Packaging & Delivery

-

Direct Time

: -

Amount(Luggage) one – 1 two – 10 >10 Est. Time(times) five thirteen To be negotiated

On the internet Customization

Goods Description

NMRV gearbox

NMRV reducer is a new kind of reducer, also recognized as RV reducer. “NMRV” is a basic term, it refers to the aluminum reducer, the world has been utilised to aluminum reducer called “NMRV reducer”. The principal elements are oil seal, oil plug, worm gear box, ball bearing, output shaft, worm wheel, worm, output shaft, motor disk (flange), output shaft include, hexagon socket head screw, double round crucial, gasket, and many others. BHADE reducer, a single of NMRV collection, has one flange input, flange output or double shaft output.

- Traits

The bodyweight of NMRV reducer is fairly mild, the shell is manufactured of aluminum alloy, which has the advantages of light-weight bodyweight, exceptional energy, exquisite visual appeal, higher warmth dissipation performance, extended support existence, noiseless motion and other benefits, hassle-free and simple link with the motor. NMRV reducer is a kind of functional transmission gear, and its appearance style and its integration are more in line with community desire than other varieties of reducer. Despite the fact that the RV reducer created of aluminum alloy only emerged in 2007, its application area and recognition are even more outstanding than other varieties of reducer. It is a type of reducer with substantial practicability and a fusion of superior technologies at home and overseas. NMRV reducer is really hassle-free to hook up with common motor, stepless gearbox and flanged electromagnetic clutch brake set. No coupling is required. Can be ideal for all – spherical installation, and the output torque is also comparatively huge, work reasonably easy and so on.

Information Images

Company

OUR Company

We are a maker in ZJ Province, China. Our organization owns the capacity of manufacturing, processing, creating and R&D. We welcome your go to.

We manage the items of energy transmission, our strains mainly protect series goods in speed reducers, gearboxes , associated electricial motors and other power transmission add-ons. Based on the flexible features, our products can be utilized in several fields: devices of squander h2o remedy, dredgers, chemical business, cranes, metal working mills, conveyors, paper industry, cement sector, cableways and so on.With the exceptional high quality and reasonable price tag , our items take pleasure in a excellent status from customers and the friends all over the planet.

Our rates are usually competitive. If the customer can location a massive order, we certainly will enable price cut.

Certifications

Packing & Delivery

FAQ

Q1: Are you a trading company or a maker ?

A: We are a producer in ZJ Province, China. Our organization owns

the capability of production, processing, creating and R&D. We welcome your check out.

Q2: How we choose designs and specs?

A: In accordance to the specific details of the requires from the element of enquiry,

we will advise the products’ models upon synthesizing the elements of

subject of goods usage, energy, torque arm and ratio…

Q3: How is your value? Can you supply any low cost?

A: Our charges are constantly aggressive. If the customer can spot a huge buy,

we surely will enable discount.

This autumn: How long should I hold out for the feedback right after I deliver the enquiry?

A: We will reply as shortly as possible, 12 hrs at most.

Q5: What is your solution warranty period?

A: We have the certifications of ISO9001,CE, SGS.

Q6: What industries are your gearboxes currently being utilized?

A: Our gearboxes are commonly applied to metallurgical equipment, mining

equipment, automation products, food machinery, packaging products,

tobacco gear and so on.

helical China gearbox pricestepless speed variator speed variator gear transmission worm cycloidal speed reducer china gear reducer – Supplier Manufacturer wholesaler Factory

For far more information.: Cellular/Whatpp: +8613083988828

How Can You Be Risk-free When Making use of PTO Shafts? First, make certain the shaft is shielded. This involves the driveline defend that handles the employ driveline, and the grasp defend which handles the universal joint and PTO stub shaft on the tractor.Maintain the protect so it can perform for you. PTO driveline shields are usually mounted on bearings, so they want to be taken care of. always REPLACE the shield when it is damaged or missing.Next, preserve a safe length from it when in use. Keep other individuals away, as well. How considerably? A distance of twice your peak is a excellent begin.Allow only individuals who totally have to be in the region to be there. Keep all children absent!Always pay interest to what is occurring. Most PTO victims were caught by surprise.If some thing goes improper — stop the machinery get the PTO out of gear, stop the engine and set the brake. Place the keys in your pocket before doing work on the machinery.When halting the machinery for any reason — stop of function, lunch, repairs, or conversation — get the PTO out of equipment, stop the engine and set the brake.Highway planers, dredges, and other products demand energy from some form of motor in order to complete their developed purpose. Without a electricity take off, it would be necessary to add a next motor to supply the energy needed to run hydraulic pumps and other driveline connected equipment.Our variety of gearboxes is divided into the pursuing categories: 1. General Purpose containers. Standard range of “T” or “L” configuration gearboxes suited for a wide assortment of programs.The team has taken component in the producing and revising of ISO/TC100 intercontinental chain regular many a long time in success and hosted the 16th ISO/TC100 Worldwide annual meeting in 2004. Our company has strong economic strength, builds up a technician crew contingent with large quality, possesses the production assembly line of technicalization in China and perfect program checking on merchandise good quality and operates marketing networks through the place.

Overview

Rapid Details