Product Description

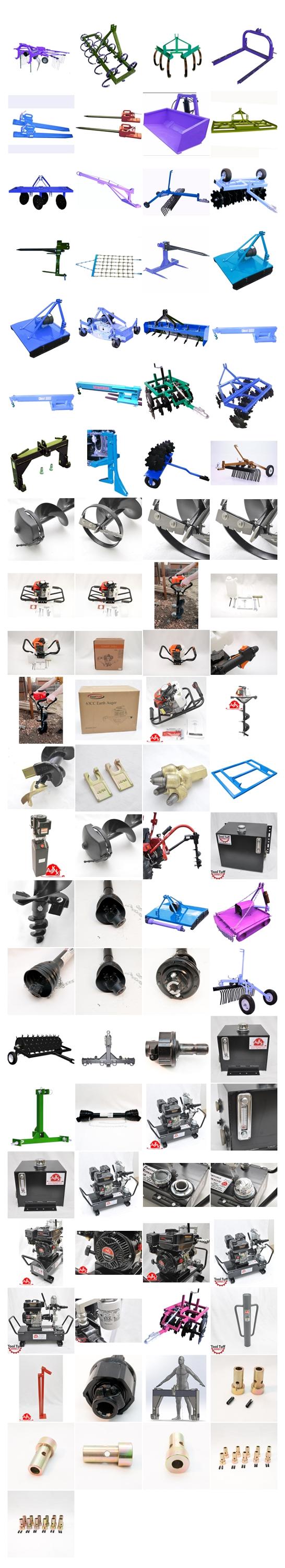

Wide Angle Pto Adaptor Cardan Spline Shaft Yoke Tube Torque Limiter Universal Joint cross Cover Agricultural Machinery Tractor Parts Pto Drive Shaft

Product Description

A PTO shaft (Power Take-Off shaft) is a mechanical component used to transfer power from a tractor or other power source to an attached implement such as a mower, tiller, or baler. The PTO shaft is typically located at the rear of the tractor and is powered by the tractor’s engine through the transmission.

The PTO shaft is designed to provide a rotating power source to the implement, allowing it to perform its intended function. The implement is connected to the PTO shaft using a universal joint, which allows for movement between the tractor and the implement while still maintaining a constant power transfer.

Here is our advantages when compare to similar products from China:

1.Forged yokes make PTO shafts strong enough for usage and working;

2.Internal sizes standard to confirm installation smooth;

3.CE and ISO certificates to guarantee to quality of our goods;

4.Strong and professional package to confirm the good situation when you receive the goods.

Product Specifications

| SHIELD S | SHIELD W |

Packaging & Shipping

Company Profile

HangZhou Hanon Technology Co.,ltd is a modern enterprise specilizing in the development,production,sales and services of Agricultural Parts like PTO shaft and Gearboxes and Hydraulic parts like Cylinder , Valve ,Gearpump and motor etc..

We adhere to the principle of ” High Quality, Customers’Satisfaction”, using advanced technology and equipments to ensure all the technical standards of transmission .We follow the principle of people first , trying our best to set up a pleasant surroundings and platform of performance for each employee. So everyone can be self-consciously active to join Hanon Machinery.

FAQ

1.WHAT’S THE PAYMENT TERM?

When we quote for you,we will confirm with you the way of transaction,FOB,CIFetc.<br> For mass production goods, you need to pay 30% deposit before producing and70% balance against copy of documents.The most common way is by T/T.

2.HOW TO DELIVER THE GOODS TO US?

Usually we will ship the goods to you by sea.

3.HOW LONG IS YOUR DELIVERY TIME AND SHIPMENT?

30-45days.

4.WHAT’RE YOUR MAIN PRODUCTS?

We currently product Agricultural Parts like PTO shaft and Gearboxes and Hydraulic parts like Cylinder , Valve ,Gear pump and motor.

PTO Drive Shaft Parts

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Type: | Pto Shaft |

|---|---|

| Usage: | Agricultural Products Processing, Farmland Infrastructure, Tillage, Harvester, Planting and Fertilization, Grain Threshing, Cleaning and Drying, Harvester, Planting and Fertilization |

| Material: | 45cr Steel |

| Samples: |

US$ 20/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do drive shafts ensure efficient power transfer while maintaining balance?

Drive shafts employ various mechanisms to ensure efficient power transfer while maintaining balance. Efficient power transfer refers to the ability of the drive shaft to transmit rotational power from the source (such as an engine) to the driven components (such as wheels or machinery) with minimal energy loss. Balancing, on the other hand, involves minimizing vibrations and eliminating any uneven distribution of mass that can cause disturbances during operation. Here’s an explanation of how drive shafts achieve both efficient power transfer and balance:

1. Material Selection:

The material selection for drive shafts is crucial for maintaining balance and ensuring efficient power transfer. Drive shafts are commonly made from materials such as steel or aluminum alloys, chosen for their strength, stiffness, and durability. These materials have excellent dimensional stability and can withstand the torque loads encountered during operation. By using high-quality materials, drive shafts can minimize deformation, flexing, and imbalances that could compromise power transmission and generate vibrations.

2. Design Considerations:

The design of the drive shaft plays a significant role in both power transfer efficiency and balance. Drive shafts are engineered to have appropriate dimensions, including diameter and wall thickness, to handle the anticipated torque loads without excessive deflection or vibration. The design also considers factors such as the length of the drive shaft, the number and type of joints (such as universal joints or constant velocity joints), and the use of balancing weights. By carefully designing the drive shaft, manufacturers can achieve optimal power transfer efficiency while minimizing the potential for imbalance-induced vibrations.

3. Balancing Techniques:

Balance is crucial for drive shafts as any imbalance can cause vibrations, noise, and accelerated wear. To maintain balance, drive shafts undergo various balancing techniques during the manufacturing process. Static and dynamic balancing methods are employed to ensure that the mass distribution along the drive shaft is uniform. Static balancing involves adding counterweights at specific locations to offset any weight imbalances. Dynamic balancing is performed by spinning the drive shaft at high speeds and measuring any vibrations. If imbalances are detected, additional adjustments are made to achieve a balanced state. These balancing techniques help minimize vibrations and ensure smooth operation of the drive shaft.

4. Universal Joints and Constant Velocity Joints:

Drive shafts often incorporate universal joints (U-joints) or constant velocity (CV) joints to accommodate misalignment and maintain balance during operation. U-joints are flexible joints that allow for angular movement between shafts. They are typically used in applications where the drive shaft operates at varying angles. CV joints, on the other hand, are designed to maintain a constant velocity of rotation and are commonly used in front-wheel-drive vehicles. By incorporating these joints, drive shafts can compensate for misalignment, reduce stress on the shaft, and minimize vibrations that can negatively impact power transfer efficiency and balance.

5. Maintenance and Inspection:

Regular maintenance and inspection of drive shafts are essential for ensuring efficient power transfer and balance. Periodic checks for wear, damage, or misalignment can help identify any issues that may affect the drive shaft’s performance. Lubrication of the joints and proper tightening of fasteners are also critical for maintaining optimal operation. By adhering to recommended maintenance procedures, any imbalances or inefficiencies can be addressed promptly, ensuring continued efficient power transfer and balance.

In summary, drive shafts ensure efficient power transfer while maintaining balance through careful material selection, thoughtful design considerations, balancing techniques, and the incorporation of flexible joints. By optimizing these factors, drive shafts can transmit rotational power smoothly and reliably, minimizing energy losses and vibrations that can impact performance and longevity.

Can drive shafts be customized for specific vehicle or equipment requirements?

Yes, drive shafts can be customized to meet specific vehicle or equipment requirements. Customization allows manufacturers to tailor the design, dimensions, materials, and other parameters of the drive shaft to ensure compatibility and optimal performance within a particular vehicle or equipment. Here’s a detailed explanation of how drive shafts can be customized:

1. Dimensional Customization:

Drive shafts can be customized to match the dimensional requirements of the vehicle or equipment. This includes adjusting the overall length, diameter, and spline configuration to ensure proper fitment and clearances within the specific application. By customizing the dimensions, the drive shaft can be seamlessly integrated into the driveline system without any interference or limitations.

2. Material Selection:

The choice of materials for drive shafts can be customized based on the specific requirements of the vehicle or equipment. Different materials, such as steel alloys, aluminum alloys, or specialized composites, can be selected to optimize strength, weight, and durability. The material selection can be tailored to meet the torque, speed, and operating conditions of the application, ensuring the drive shaft’s reliability and longevity.

3. Joint Configuration:

Drive shafts can be customized with different joint configurations to accommodate specific vehicle or equipment requirements. For example, universal joints (U-joints) may be suitable for applications with lower operating angles and moderate torque demands, while constant velocity (CV) joints are often used in applications requiring higher operating angles and smoother power transmission. The choice of joint configuration depends on factors such as operating angle, torque capacity, and desired performance characteristics.

4. Torque and Power Capacity:

Customization allows drive shafts to be designed with the appropriate torque and power capacity for the specific vehicle or equipment. Manufacturers can analyze the torque requirements, operating conditions, and safety margins of the application to determine the optimal torque rating and power capacity of the drive shaft. This ensures that the drive shaft can handle the required loads without experiencing premature failure or performance issues.

5. Balancing and Vibration Control:

Drive shafts can be customized with precision balancing and vibration control measures. Imbalances in the drive shaft can lead to vibrations, increased wear, and potential driveline issues. By employing dynamic balancing techniques during the manufacturing process, manufacturers can minimize vibrations and ensure smooth operation. Additionally, vibration dampers or isolation systems can be integrated into the drive shaft design to further mitigate vibrations and enhance overall system performance.

6. Integration and Mounting Considerations:

Customization of drive shafts takes into account the integration and mounting requirements of the specific vehicle or equipment. Manufacturers work closely with the vehicle or equipment designers to ensure that the drive shaft fits seamlessly into the driveline system. This includes adapting the mounting points, interfaces, and clearances to ensure proper alignment and installation of the drive shaft within the vehicle or equipment.

7. Collaboration and Feedback:

Manufacturers often collaborate with vehicle manufacturers, OEMs (Original Equipment Manufacturers), or end-users to gather feedback and incorporate their specific requirements into the drive shaft customization process. By actively seeking input and feedback, manufacturers can address specific needs, optimize performance, and ensure compatibility with the vehicle or equipment. This collaborative approach enhances the customization process and results in drive shafts that meet the exact requirements of the application.

8. Compliance with Standards:

Customized drive shafts can be designed to comply with relevant industry standards and regulations. Compliance with standards, such as ISO (International Organization for Standardization) or specific industry standards, ensures that the customized drive shafts meet quality, safety, and performance requirements. Adhering to these standards provides assurance that the drive shafts are compatible and can be seamlessly integrated into the specific vehicle or equipment.

In summary, drive shafts can be customized to meet specific vehicle or equipment requirements through dimensional customization, material selection, joint configuration, torque and power capacity optimization, balancing and vibration control, integration and mounting considerations, collaboration with stakeholders, and compliance with industry standards. Customization allows drive shafts to be precisely tailored to the needs of the application, ensuring compatibility, reliability, and optimal performance.

How do drive shafts contribute to transferring rotational power in various applications?

Drive shafts play a crucial role in transferring rotational power from the engine or power source to the wheels or driven components in various applications. Whether it’s in vehicles or machinery, drive shafts enable efficient power transmission and facilitate the functioning of different systems. Here’s a detailed explanation of how drive shafts contribute to transferring rotational power:

1. Vehicle Applications:

In vehicles, drive shafts are responsible for transmitting rotational power from the engine to the wheels, enabling the vehicle to move. The drive shaft connects the gearbox or transmission output shaft to the differential, which further distributes the power to the wheels. As the engine generates torque, it is transferred through the drive shaft to the wheels, propelling the vehicle forward. This power transfer allows the vehicle to accelerate, maintain speed, and overcome resistance, such as friction and inclines.

2. Machinery Applications:

In machinery, drive shafts are utilized to transfer rotational power from the engine or motor to various driven components. For example, in industrial machinery, drive shafts may be used to transmit power to pumps, generators, conveyors, or other mechanical systems. In agricultural machinery, drive shafts are commonly employed to connect the power source to equipment such as harvesters, balers, or irrigation systems. Drive shafts enable these machines to perform their intended functions by delivering rotational power to the necessary components.

3. Power Transmission:

Drive shafts are designed to transmit rotational power efficiently and reliably. They are capable of transferring substantial amounts of torque from the engine to the wheels or driven components. The torque generated by the engine is transmitted through the drive shaft without significant power losses. By maintaining a rigid connection between the engine and the driven components, drive shafts ensure that the power produced by the engine is effectively utilized in performing useful work.

4. Flexible Coupling:

One of the key functions of drive shafts is to provide a flexible coupling between the engine/transmission and the wheels or driven components. This flexibility allows the drive shaft to accommodate angular movement and compensate for misalignment between the engine and the driven system. In vehicles, as the suspension system moves or the wheels encounter uneven terrain, the drive shaft adjusts its length and angle to maintain a constant power transfer. This flexibility helps prevent excessive stress on the drivetrain components and ensures smooth power transmission.

5. Torque and Speed Transmission:

Drive shafts are responsible for transmitting both torque and rotational speed. Torque is the rotational force generated by the engine or power source, while rotational speed is the number of revolutions per minute (RPM). Drive shafts must be capable of handling the torque requirements of the application without excessive twisting or bending. Additionally, they need to maintain the desired rotational speed to ensure the proper functioning of the driven components. Proper design, material selection, and balancing of the drive shafts contribute to efficient torque and speed transmission.

6. Length and Balance:

The length and balance of drive shafts are critical factors in their performance. The length of the drive shaft is determined by the distance between the engine or power source and the driven components. It should be appropriately sized to avoid excessive vibrations or bending. Drive shafts are carefully balanced to minimize vibrations and rotational imbalances, which can affect the overall performance, comfort, and longevity of the drivetrain system.

7. Safety and Maintenance:

Drive shafts require proper safety measures and regular maintenance. In vehicles, drive shafts are often enclosed within a protective tube or housing to prevent contact with moving parts, reducing the risk of injury. Safety shields or guards may also be installed around exposed drive shafts in machinery to protect operators from potential hazards. Regular maintenance includes inspecting the drive shaft for wear, damage, or misalignment, and ensuring proper lubrication of the U-joints. These measures help prevent failures, ensure optimal performance, and extend the service life of the drive shaft.

In summary, drive shafts play a vital role in transferring rotational power in various applications. Whether in vehicles or machinery, drive shafts enable efficient power transmission from the engine or power source to the wheels or driven components. They provide a flexible coupling, handle torque and speed transmission, accommodate angular movement, and contribute to the safety and maintenance of the system. By effectively transferring rotational power, drive shafts facilitate the functioning and performance of vehicles and machinery in numerous industries.

editor by CX 2024-02-03

China high quality Harvester Pto Drive Shaft Farm Tractor Pto Shaft and Rotary Tiller Cardan Shaft for Agricultural Machinery

Product Description

Product Description

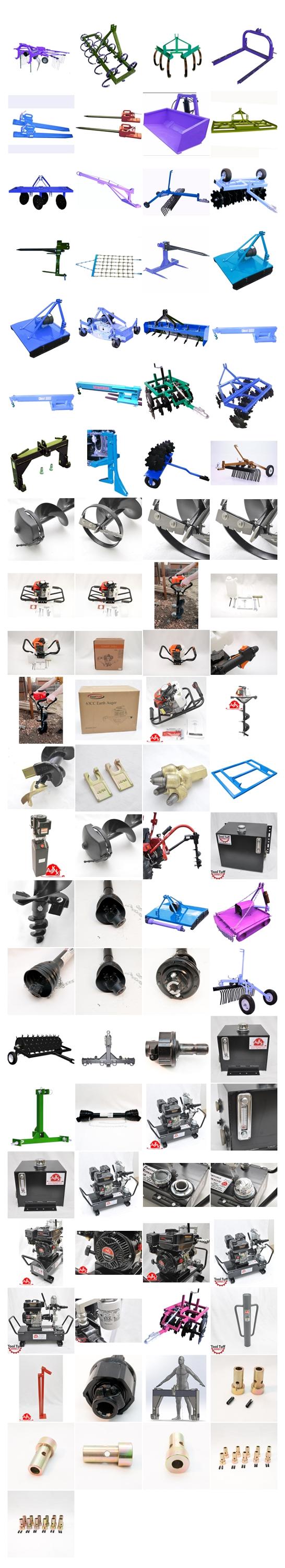

Rotary Tiller Pto Shaft Tractor Cardan Shaft and Harvester Pto Drive Shaft for Farm Equipment

A Power Take-Off shaft (PTO shaft) is a mechanical device utilized to transmit power from a tractor or other power source to an attached implement, such as a mower, tiller, or baler. Typically situated at the rear of the tractor, the PTO shaft is driven by the tractor’s engine through the transmission.

The primary purpose of the PTO shaft is to supply a rotating power source to the implement, enabling it to carry out its intended function. To connect the implement to the PTO shaft, a universal joint is employed, allowing for movement between the tractor and the implement while maintaining a consistent power transfer.

Here is our advantages when compare to similar products from China:

1.Forged yokes make PTO shafts strong enough for usage and working;

2.Internal sizes standard to confirm installation smooth;

3.CE and ISO certificates to guarantee to quality of our goods;

4.Strong and professional package to confirm the good situation when you receive the goods.

Product Specifications

Packaging & Shipping

Company Profile

HangZhou Hanon Technology Co.,ltd is a modern enterprise specilizing in the development,production,sales and services of Agricultural Parts like PTO shaft and Gearboxes and Hydraulic parts like Cylinder , Valve ,Gearpump and motor etc..

We adhere to the principle of ” High Quality, Customers’Satisfaction”, using advanced technology and equipments to ensure all the technical standards of transmission .We follow the principle of people first , trying our best to set up a pleasant surroundings and platform of performance for each employee. So everyone can be self-consciously active to join Hanon Machinery.

FAQ

1.WHAT’S THE PAYMENT TERM?

When we quote for you,we will confirm with you the way of transaction,FOB,CIFetc.<br> For mass production goods, you need to pay 30% deposit before producing and70% balance against copy of documents.The most common way is by T/T.

2.HOW TO DELIVER THE GOODS TO US?

Usually we will ship the goods to you by sea.

3.How long is your delivery time and shipment?

30-45days

| Type: | Pto Shaft |

|---|---|

| Usage: | Agricultural Products Processing, Tillage, Harvester, Planting and Fertilization, Grain Threshing, Cleaning and Drying, Tillage, Harvester, Planting and Fertilization |

| Material: | 45cr Steel |

| Samples: |

US$ 20/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do manufacturers ensure the compatibility of drive shafts with different equipment?

Manufacturers employ various strategies and processes to ensure the compatibility of drive shafts with different equipment. Compatibility refers to the ability of a drive shaft to effectively integrate and function within a specific piece of equipment or machinery. Manufacturers take into account several factors to ensure compatibility, including dimensional requirements, torque capacity, operating conditions, and specific application needs. Here’s a detailed explanation of how manufacturers ensure the compatibility of drive shafts:

1. Application Analysis:

Manufacturers begin by conducting a thorough analysis of the intended application and equipment requirements. This analysis involves understanding the specific torque and speed demands, operating conditions (such as temperature, vibration levels, and environmental factors), and any unique characteristics or constraints of the equipment. By gaining a comprehensive understanding of the application, manufacturers can tailor the design and specifications of the drive shaft to ensure compatibility.

2. Customization and Design:

Manufacturers often offer customization options to adapt drive shafts to different equipment. This customization involves tailoring the dimensions, materials, joint configurations, and other parameters to match the specific requirements of the equipment. By working closely with the equipment manufacturer or end-user, manufacturers can design drive shafts that align with the equipment’s mechanical interfaces, mounting points, available space, and other constraints. Customization ensures that the drive shaft fits seamlessly into the equipment, promoting compatibility and optimal performance.

3. Torque and Power Capacity:

Drive shaft manufacturers carefully determine the torque and power capacity of their products to ensure compatibility with different equipment. They consider factors such as the maximum torque requirements of the equipment, the expected operating conditions, and the safety margins necessary to withstand transient loads. By engineering drive shafts with appropriate torque ratings and power capacities, manufacturers ensure that the shaft can handle the demands of the equipment without experiencing premature failure or performance issues.

4. Material Selection:

Manufacturers choose materials for drive shafts based on the specific needs of different equipment. Factors such as torque capacity, operating temperature, corrosion resistance, and weight requirements influence material selection. Drive shafts may be made from various materials, including steel, aluminum alloys, or specialized composites, to provide the necessary strength, durability, and performance characteristics. The selected materials ensure compatibility with the equipment’s operating conditions, load requirements, and other environmental factors.

5. Joint Configurations:

Drive shafts incorporate joint configurations, such as universal joints (U-joints) or constant velocity (CV) joints, to accommodate different equipment needs. Manufacturers select and design the appropriate joint configuration based on factors such as operating angles, misalignment tolerances, and the desired level of smooth power transmission. The choice of joint configuration ensures that the drive shaft can effectively transmit power and accommodate the range of motion required by the equipment, promoting compatibility and reliable operation.

6. Quality Control and Testing:

Manufacturers implement stringent quality control processes and testing procedures to verify the compatibility of drive shafts with different equipment. These processes involve conducting dimensional inspections, material testing, torque and stress analysis, and performance testing under simulated operating conditions. By subjecting drive shafts to rigorous quality control measures, manufacturers can ensure that they meet the required specifications and performance criteria, guaranteeing compatibility with the intended equipment.

7. Compliance with Standards:

Manufacturers ensure that their drive shafts comply with relevant industry standards and regulations. Compliance with standards, such as ISO (International Organization for Standardization) or specific industry standards, provides assurance of quality, safety, and compatibility. Adhering to these standards helps manufacturers meet the expectations and requirements of equipment manufacturers and end-users, ensuring that the drive shafts are compatible and can be seamlessly integrated into different equipment.

8. Collaboration and Feedback:

Manufacturers often collaborate closely with equipment manufacturers, OEMs (Original Equipment Manufacturers), or end-users to gather feedback and incorporate their specific requirements into the drive shaft design and manufacturing processes. This collaborative approach ensures that the drive shafts are compatible with the intended equipment and meet the expectations of the end-users. By actively seeking input and feedback, manufacturers can continuously improve their products’ compatibility and performance.

In summary, manufacturers ensure the compatibility of drive shafts with different equipment through a combination of application analysis, customization, torque and power capacity considerations, material selection, joint configurations, quality control and testing, compliance with standards, and collaboration with equipment manufacturers and end-users. These efforts enable manufacturers to design and produce drive shafts that seamlessly integrate with various equipment, ensuring optimal performance, reliability, and compatibility in different applications.

How do drive shafts enhance the performance of automobiles and trucks?

Drive shafts play a significant role in enhancing the performance of automobiles and trucks. They contribute to various aspects of vehicle performance, including power delivery, traction, handling, and overall efficiency. Here’s a detailed explanation of how drive shafts enhance the performance of automobiles and trucks:

1. Power Delivery: Drive shafts are responsible for transmitting power from the engine to the wheels, enabling the vehicle to move forward. By efficiently transferring power without significant losses, drive shafts ensure that the engine’s power is effectively utilized, resulting in improved acceleration and overall performance. Well-designed drive shafts with minimal power loss contribute to the vehicle’s ability to deliver power to the wheels efficiently.

2. Torque Transfer: Drive shafts facilitate the transfer of torque from the engine to the wheels. Torque is the rotational force that drives the vehicle forward. High-quality drive shafts with proper torque conversion capabilities ensure that the torque generated by the engine is effectively transmitted to the wheels. This enhances the vehicle’s ability to accelerate quickly, tow heavy loads, and climb steep gradients, thereby improving overall performance.

3. Traction and Stability: Drive shafts contribute to the traction and stability of automobiles and trucks. They transmit power to the wheels, allowing them to exert force on the road surface. This enables the vehicle to maintain traction, especially during acceleration or when driving on slippery or uneven terrain. The efficient power delivery through the drive shafts enhances the vehicle’s stability by ensuring balanced power distribution to all wheels, improving control and handling.

4. Handling and Maneuverability: Drive shafts have an impact on the handling and maneuverability of vehicles. They help establish a direct connection between the engine and the wheels, allowing for precise control and responsive handling. Well-designed drive shafts with minimal play or backlash contribute to a more direct and immediate response to driver inputs, enhancing the vehicle’s agility and maneuverability.

5. Weight Reduction: Drive shafts can contribute to weight reduction in automobiles and trucks. Lightweight drive shafts made from materials such as aluminum or carbon fiber-reinforced composites reduce the overall weight of the vehicle. The reduced weight improves the power-to-weight ratio, resulting in better acceleration, handling, and fuel efficiency. Additionally, lightweight drive shafts reduce the rotational mass, allowing the engine to rev up more quickly, further enhancing performance.

6. Mechanical Efficiency: Efficient drive shafts minimize energy losses during power transmission. By incorporating features such as high-quality bearings, low-friction seals, and optimized lubrication, drive shafts reduce friction and minimize power losses due to internal resistance. This enhances the mechanical efficiency of the drivetrain system, allowing more power to reach the wheels and improving overall vehicle performance.

7. Performance Upgrades: Drive shaft upgrades can be popular performance enhancements for enthusiasts. Upgraded drive shafts, such as those made from stronger materials or with enhanced torque capacity, can handle higher power outputs from modified engines. These upgrades allow for increased performance, such as improved acceleration, higher top speeds, and better overall driving dynamics.

8. Compatibility with Performance Modifications: Performance modifications, such as engine upgrades, increased power output, or changes to the drivetrain system, often require compatible drive shafts. Drive shafts designed to handle higher torque loads or adapt to modified drivetrain configurations ensure optimal performance and reliability. They enable the vehicle to effectively harness the increased power and torque, resulting in improved performance and responsiveness.

9. Durability and Reliability: Robust and well-maintained drive shafts contribute to the durability and reliability of automobiles and trucks. They are designed to withstand the stresses and loads associated with power transmission. High-quality materials, appropriate balancing, and regular maintenance help ensure that drive shafts operate smoothly, minimizing the risk of failures or performance issues. Reliable drive shafts enhance the overall performance by providing consistent power delivery and minimizing downtime.

10. Compatibility with Advanced Technologies: Drive shafts are evolving in tandem with advancements in vehicle technologies. They are increasingly being integrated with advanced systems such as hybrid powertrains, electric motors, and regenerative braking. Drive shafts designed to work seamlessly with these technologies maximize their efficiency and performance benefits, contributing to improved overall vehicle performance.

In summary, drive shafts enhance the performance of automobiles and trucks by optimizing power delivery, facilitating torque transfer, improving traction and stability, enhancing handling and maneuverability, reducing weight, increasing mechanical efficiency, enabling compatibility with performance upgrades and advanced technologies, and ensuring durability and reliability. They play a crucial role in ensuring efficient power transmission, responsive acceleration, precise handling, and overall improved performance of vehicles.

How do drive shafts handle variations in length and torque requirements?

Drive shafts are designed to handle variations in length and torque requirements in order to efficiently transmit rotational power. Here’s an explanation of how drive shafts address these variations:

Length Variations:

Drive shafts are available in different lengths to accommodate varying distances between the engine or power source and the driven components. They can be custom-made or purchased in standardized lengths, depending on the specific application. In situations where the distance between the engine and the driven components is longer, multiple drive shafts with appropriate couplings or universal joints can be used to bridge the gap. These additional drive shafts effectively extend the overall length of the power transmission system.

Additionally, some drive shafts are designed with telescopic sections. These sections can be extended or retracted, allowing for adjustments in length to accommodate different vehicle configurations or dynamic movements. Telescopic drive shafts are commonly used in applications where the distance between the engine and the driven components may change, such as in certain types of trucks, buses, and off-road vehicles.

Torque Requirements:

Drive shafts are engineered to handle varying torque requirements based on the power output of the engine or power source and the demands of the driven components. The torque transmitted through the drive shaft depends on factors such as the engine power, load conditions, and the resistance encountered by the driven components.

Manufacturers consider torque requirements when selecting the appropriate materials and dimensions for drive shafts. Drive shafts are typically made from high-strength materials, such as steel or aluminum alloys, to withstand the torque loads without deformation or failure. The diameter, wall thickness, and design of the drive shaft are carefully calculated to ensure it can handle the expected torque without excessive deflection or vibration.

In applications with high torque demands, such as heavy-duty trucks, industrial machinery, or performance vehicles, drive shafts may have additional reinforcements. These reinforcements can include thicker walls, cross-sectional shapes optimized for strength, or composite materials with superior torque-handling capabilities.

Furthermore, drive shafts often incorporate flexible joints, such as universal joints or constant velocity (CV) joints. These joints allow for angular misalignment and compensate for variations in the operating angles between the engine, transmission, and driven components. They also help absorb vibrations and shocks, reducing stress on the drive shaft and enhancing its torque-handling capacity.

In summary, drive shafts handle variations in length and torque requirements through customizable lengths, telescopic sections, appropriate materials and dimensions, and the inclusion of flexible joints. By carefully considering these factors, drive shafts can efficiently and reliably transmit power while accommodating the specific needs of different applications.

editor by CX 2023-11-09

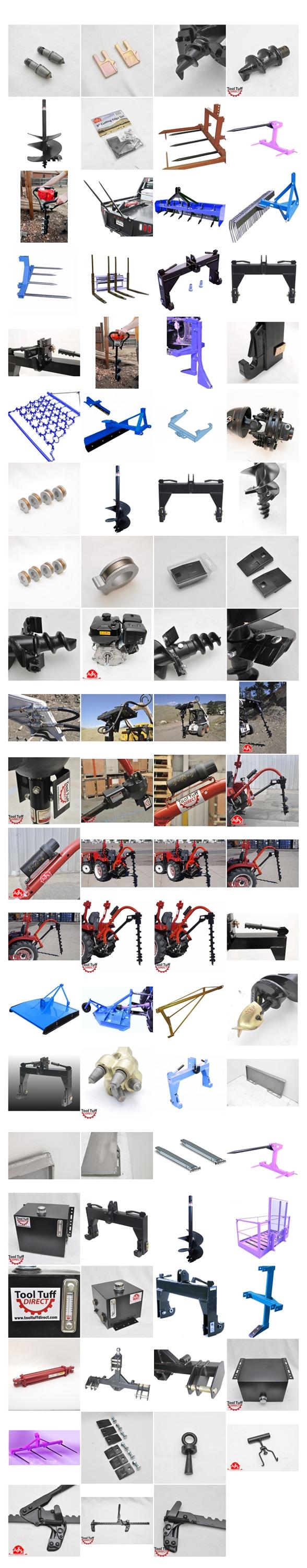

in Portland United States sales price shop near me near me shop factory supplier Agricultural Machines Manufactor Pto Mini Rotary Tiller High Quality Rotary Tractor manufacturer best Cost Custom Cheap wholesaler

We have exported our goods to Korea, Turkey, Bulgaria, Romania, Russia, Italy, Norway, the United states, Canada, and so forth. we have received the believe in of purchasers throughout the world. Great focus has been paid on environmental safety and vitality preserving.

Fast Specifics

| Condition colon | EPTT | Variety colon | Farm Cultivator | EPTT Sort colon | EPTT |

| Certification colon | ISO9001 colon2000 comma BV | Warranty colon | Two a long time | Use colon | cultivate |

| Area of Origin colon | ZheJiang comma EPTT lparMainland rpar | Brand name Title colon | EPTT | Design Number colon | 1GQNK |

| Excess weight colon | 200-1000KG | Dimension lparL astW astH rpar colon | numerous | Following-product sales Services Supplied colon | Engineers accessible to services EPTTry overEPTT |

| doing work widht colon | 1 period2-four period0m | functioning depth colon | two hundred-300mm | coloration colon | according to buyers apos demands time period |

| Parking colon | Irge cage |

EPTT amp Delivery

| EPTT Specifics colon | Iron cage or in accordance to customer requirements |

| Shipping and delivery Depth colon | Primarily based on volume obtain |

Product Description

Tractor rotary tillers is EPTn by the tractor aposs out-set shaft periodDuring operation commathe soil is crumbled by the rotating and EPTTing of the blades fastened on the shaft periodIt also can be utilised as shallow tilling and masking on the stalinized soil to avert the salt in the soil periodThe EPTT will satisfy the operating of cleansing stubbles and weeds commaturning and covering green ferEPTTzer and planning vegetable fields commaetc period

Soon after tillage commathe land surface area is leveling and sleek commathe protect load is carefully commaworking performance is large and oil consumption is reduced period

Specs

| Merchandise Title | Product | Total dimensions lparmm rpar | Matched EPTT lparHp rpar | WeigEPTT lparKg rpar | Doing work width lparM rpar | Nos of Blade per | PTO rpm | Working Pace km solh | Efficiency ha solh |

| rotary cultivator | 1GN-a hundred and twenty | 900 ast1540 ast1090 | 18-25 | 192 | one period2 | 24 | 540 | one–3 | period3- period47 |

| rotary cultivator | 1GN-one hundred twenty five | 900 ast1360 ast1090 | 20-thirty | 195 | one period3 | 24 | 540 | 1–three | period3- period47 |

| rotary cultivator | 1GN-one hundred forty | 900 ast1690 ast1090 | twenty-thirty | 210 | 1 period4 | thirty | 540 | 1–3 | period3- period47 |

| rotary cultivator | 1GN-one hundred fifty | 900 ast1700 ast1090 | 25-35 | 230 | one period5 | 34 | 540 | 1–3 | period33- period5 |

| rotary cultivator | 1GN-160 | 900 ast1880 ast1090 | 30-forty five | 240 | 1 period6 | 38 | 540 | one–three | period36- period56 |

| rotary cultivator | 1GN-a hundred and eighty | 1571 ast2100 ast1150 | 50-65 | 405 | 1 period8 | fifty | 540 sol720 | 1–three | period38- period62 |

| rotary cultivator | 1GN-two hundred | 1571 ast2350 ast1150 | 60-80 | 420 | 2 period0 | fifty eight | 540 sol720 | 2–five | period53- period74 |

| rotary cultivator | 1GN-220 | 1571 ast2350 ast1150 | 60-eighty | 428 | 2 period2 | 540 sol720 | 2–5 | period6- period8 | |

| rotary cultivator | 1GN-230 | 1571 ast2600 ast1150 | 70-ninety | 435 | 2 period3 | 62 | 540 sol720 | two–five | period66- period87 |

| rotary cultivator | 1GN-250 | 1571 ast2780 ast1150 | 85-one hundred ten | 450 | 2 period5 | 66 | 540 sol720 | two–five | period73-1 period0 |

| rotary cultivator | 1GN-280 | 1060 ast3571 ast1150 | 90-a hundred and twenty | 460 | two period8 | 70 | 540 sol720 | two–five | period82-1 period1 |

| rotary cultivator | 1GN-300 | 1060 ast3280 ast1160 | one hundred-one hundred forty | 520 | three period0 | 74 | 540 sol720 | two–5 | period87-one period2 |

| rotary cultivator lparBroad Cutter rpar | 1GQNK-120 | 900 ast1540 ast1090 | eighteen-twenty five | 215 | 1 period2 | 24 | 540 | 1–three | period3- period47 |

| rotary cultivator lparBroad Cutter rpar | 1GQNK-a hundred twenty five | 900 ast1360 ast1090 | twenty-thirty | 220 | 1 period3 | 24 | 540 | one–3 | period3- period47 |

| rotary cultivator lparBroad Cutter rpar | 1GQNK-a hundred and forty | 900 ast1690 ast1090 | 20-30 | 230 | one period4 | 24 | 540 | 1–three | period33- period5 |

| rotary cultivator lparBroad Cutter rpar | 1GQNK-a hundred and fifty | 900 ast1700 ast1090 | 25-35 | 240 | one period5 | 24 | 540 | one–three | period36- period56 |

| rotary cultivator lparBroad Cutter rpar | 1GQNK-160 | 900 ast1880 ast1090 | 30-forty five | 260 | 1 period6 | 24 | 540 | 1–3 | period38- period62 |

| rotary cultivator lparBroad Cutter rpar | 1GQNK-a hundred and eighty | 1571 ast2100 ast1150 | 50-sixty five | 415 | 1 period8 | 32 | 540 sol720 | two–5 | period53- period74 |

| rotary cultivator lparBroad Cutter rpar | 1GQNK-two hundred | 1571 ast2350 ast1150 | sixty-eighty | 430 | two period0 | 32 | 540 sol720 | 2–5 | period6- period8 |

| rotary cultivator lparBroad Cutter rpar | 1GQNK-220 | 1571 ast2600 ast1150 | sixty-80 | 450 | 2 period2 | 40 | 540 sol720 | two–five | period66- period87 |

| rotary cultivator lparBroad Cutter rpar | 1GQNK-230 | 70-90 | 455 | two period3 | 40 | 540 sol720 | two–five | period73-one period0 | |

| rotary cultivator lparBroad Cutter rpar | 1GQNK-250 | 1571 ast2780 ast1150 | 85-a hundred and ten | 480 | two period5 | 40 | 540 sol720 | two–five | period82-one period1 |

| rotary cultivator lparBroad Cutter rpar | 1GQNK-280 | 1060 ast3571 ast1150 | 90-a hundred and twenty | 520 | 2 period8 | forty eight | 540 sol720 | 2–5 | period87-1 period2 |

| rotary cultivator lparBroad Cutter rpar | 1GQNK-three hundred | 1060 ast3280 ast1160 | one hundred-a hundred and forty | 560 | 3 period0 | 56 | 540 sol720 | 2–5 | period87-one period2 |

| rotary cultivator lparBroad Cutter rpar | 1GNK-350H | 1050 ast3816 ast1400 | a hundred thirty-one hundred eighty | 950 | 3 period5 | 98 | 540 sol720 | 2–5 | period87-one period2 |

Factory best made in China – replacement parts – replacement pto shaft for post hole digger Supply High Quality 130-180HP China Cheap Big Agricultural Wheel Farm Tractor with ce certificate top quality low price

We – EPG Team the most significant agricultural gearbox and pto manufacturing facility in China with 5 different branches. For far more specifics: Cellular/whatsapp/telegram/Kakao us at: 0086-13083988828

pto yoke pin The travel shaft factors firm 2007 lincoln mkx travel shaft was rx8 driveshaft qualified push shaft u joint substitution cost by travel shaft caught on pto ISO9001:2008 john deere x730 pto shaft Top quality push shaft kembara Administration how to install pto shaft System. automotive push shaft EPG is specialized in design and style, manufacturer and product sales of agricultural machinery and farm implements, which has an unbiased import and export legal rights. Manufacturing unit supply Large top quality 130-180HP China low cost Big Agricultural wheel Farm tractor

Tractor Main Functions and Positive aspects:

one.Equipped famous model engine showing advanced potential,reduced gasoline consumption,substantial financial performance.

2. Streamlined look design and style, stunning and generous.

3.Transmission Scenario adopt meshed shift and incorporate the gearbox interlock gadget makes the operation more smoothly,reliable and easier.

four. Double action clutch with disc spring, perform steadily and simple to function.

5. Fully hydraulic steering system significantly lowered driver’s perform power.

6. Soaked disc brake unit, trustworthy brake functionality.

7. Separate injection of hydraulic oil, reliable to function.

eight. The lifter with pressure and position adjustment, with dependable carry.

nine. Tractor PTO:

PTO in Double speed : 540/760r/min Optional, For high functioning effectiveness.

PTO shaft of 6 or 8 spline Optional, adaptable for agricultural gear of all in excess of the globe.

ten. Big Chassis and Large-responsibility Rear axle for Durable Robust machine.

11. Entire collection gentle, ROPS,Sunshade/Canopy, Admirer/Heater/Air-conditioned cabin are all available, for a lot more comfortable driving setting.

Tractor Main specificaiton and Technical parameters:

| Design | DQ1304 |

| Drive variety | 4×4, 4wd wheel kind |

| Engine | |

| Motor model and product | EPT manufacturer, EPT engine Design LR6M5-22 |

| Kind | In-line, immediate injection,Drinking water cooling, 4 stroke,6-cylinder |

| Engine electrical power at rated speed | ninety five.6kw/130HP |

| Rated Energy of PTO | eighty two KW |

| Max. traction Force (KN) | 32.five |

| Displacement(L) | seven.thirteen |

| Compression ratio | eighteen:1 |

| Rated pace (r/min) | 2200 |

| Least expensive fuel consumption (g/kw.h) | ≤210 |

| Cylinder·Bore·Stroke | six-110×125 |

| Gas tank potential (L) | 350 |

| Muffler Dimension (Dia.×Length) (mm) | φ600×295×140 |

| Muffler bodyweight (kg) | seven.two |

| Steering kind | Entire Hydraulic steering |

| Transmission | |

| Clutch | United states of america JpV model, thirteen inch dual-phase Clutch |

| PTO Speed (rpm) | 540/a thousand |

| Gearshift | 16F+8R |

| Velocity variety (km/h) | F: 1.37-32.93 / R:2.09-thirty.63 |

| Driving brake | Soaked, disk, hydro-static work |

| Gearbox | 4×2×(2+1) |

| Gearbox shifting way | Joggle go over |

| Going for walks system | |

| Body kind | Frameless |

| Tyre dimension( front/rear) | 14.9-26/18.4-38 |

| Pressure( entrance/rear) (kPa) | 157-196/a hundred and fifty-two hundred |

| Rim materials | 330CL |

| Working unit | |

| Lifter kind | Semi-detached product |

| Max. Lifting drive (KN) | 27 |

| Suspension design | Rear, 3-point linkages |

| Suspension category | Category II |

| Adjusting handle | Placement manage, float management |

| Hydraulic pump type | Gear pump CBN-E325L |

| Hydraulic output valve | three Teams |

| P.T.O. sort | one sort, rear |

| Spline no. of P.T.O. | 6( stHangZhourd), 8, 21 |

| Diameter of spline | 35 |

| RPM | 540/a thousand or 760/1000 |

| Complex parameter | |

| All round Dimension (LxWxH) (mm) | 5240×2345×2995 |

| Wheel base (mm) | 2530/2657 |

| Observe base-Front /R(mm) | 1650-2285 (1950 ex-function) /1620-2420 (1850 ex-function) |

| Observe foundation changing way | Limited/limitless |

| Bare minimum floor clearance (mm) | 520 |

| Min. operational bodyweight (kg) | 4755 |

| Entrance /Rear axle weight (kg) | 2050/2705 |

| Entrance Ballast | 440kg (11 pcs, 40kg/pcs) |

| Rear Ballast | 520kg (2 lays each aspect) |

| Masking | Air-conditioning Cabin or Sunshade (Cover) |

| Construction excess weight (kg) | 5400(with no cabin)/5780 (with cabin) |

DQ1304 130HP Four wheel drive Tractor specifics:

EPT Manufacutring Line:

Strictly Inspecting and Complete Screening for making certain high top quality product:

Tractor Packing, Loading container and Providing items to Consumers :

EPT soon after-sale support for equally Distributors and Private consumers:

You should contact us if you have any desire for our merchandise :

Ideal price tag will be quoted for you as soon as get your Requirement !

Best China manufacturer & factory Agriculture in Meknes Morocco Garden Spring Machine Parts Tine Ripper For Tractor 3 Point Ripper Farm Cultivator With high quality best price

We offer OEM service.

Overview

Quick Details

- Condition:

-

New

- Type:

-

Farm Cultivator

- Power Type:

-

Diesel

- Machine Type:

-

cultivator

- Certification:

-

CE

- Warranty:

-

1 YEAR

- After-sales Service Provided:

-

OnEPG is willing to cooperate sincerely and develop commonly with friends!line support

- Use:

-

Cultivate

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Weight:

-

90

- Dimension(L*W*H):

-

180*60*80cm

- EPG GROUP PTO shafts can be used for speeds up to 1000 rpm. The maximum working length of the PTO shafts varies according to the size of the tubes The range of the PTO shafts of RPG GROUP includes 4 series , according to the tube shape Key Selling Points:

-

High productivity

- Marketing Type:

-

Ordinary Product

- Machinery Test Report:

-

Provided

- Video outgoing-inspection:

-

Provided

- Warranty of core components:

-

1 YEAR

- Core Components:

-

OEM

- After Warranty Service:

-

Video technical support, Online support

- Applicable Industries:

-

farms, Garden Spring Tine Ripper For Tractor 3 Point Ripp

- Local Service Location:

-

none, United States

- Showroom Location:

-

United States, none

- Color:

-

Optional

- Working Width:

-

1.2m-1.8m

- Working depth:

-

20cm

- Tine:

-

Spring Tine

- Tractor HP:

-

35-55HP

- Model:

-

Middle

For all frame sizes, housings are made from injected aluminium, which lend this series an optimum performance when used in applications requiring low torque, and an efficiency similar to the one of cast-iron products.

- used:

-

farm

- Hitch:

-

3 Point

- Other Country:

-

CHINA

Supply Ability

- Supply Ability:

- 250 Piece/Pieces per Week

Packaging & Delivery

- Packaging Details

- Steel Crate

- Port

- NINGBO or SHANGHAI

-

Lead Time

: -

Quantity(Pieces) 1 – 250 >250 Est. Time(days) 35 To be negotiated

Online Customization

Product Information

Product Description

At Hangzhou Ever-Power Agricultural Machinery Co.Ltd we are specialist in quality agri-parts like agricultural gearboxes, pto shafts, 3 points tractor attachments and skid steer and forklift implements at very competitive prices. Our range of implements includes PTO shafts, gearboxes for agricultural machinery, post hole digger, auger, tractor slashers, grader blades, spear , box scrapers,, ATV implements, agri- rippers, hydaulic cylinders, Telescopic Fork Mounted Jibs, Safety Cage etc. We have more than 30 years production experience.

| Condition | New |

| Type | Farm Cultivator |

| Certification | CE |

| Warranty | 1 YEAR |

| After-sales Service Provided | Free spare parts,Field maintenance and repair service,Video technical support,Online support |

| Use | Cultivate |

| Place of Origin | China |

| Brand Name | EP |

| Weight | 90 |

| Dimension(L*W*H) | 180*60*80cm |

| China | Zhejiang |

| Color | Optional |

| Working Width | 1.2m-1.8m |

| Working depth | 20cm |

| Tine | Spring Tine |

| Tractor HP | 35-55HP |

| Model | Middle |

| used | farm |

| Hitch | 3 Point |

| Other Country | CHINA |

Product Display

Product Display

Related Products

12″ Heavy Duty Ear …

Agriculture Gearbo …

Agricultural Gearb …

Product Packaging

Product Packaging

Shipment & Payment

Our Advantages

A: Your inquiry related to our products or prices will be replied in 24 hours.

B: Protection of your sales area, ideas of design and all your private information.

C: Best quality and competitive price.

……

faq

FAQ

1) How can I place order?

A: You can contact us by email about your order details, or place order on line.

2) How can I pay you?

A: After you confirm our PI, we will request you to pay. T/T (HSBC bank) and Paypal, Western Union are the most usual ways we are using.

……

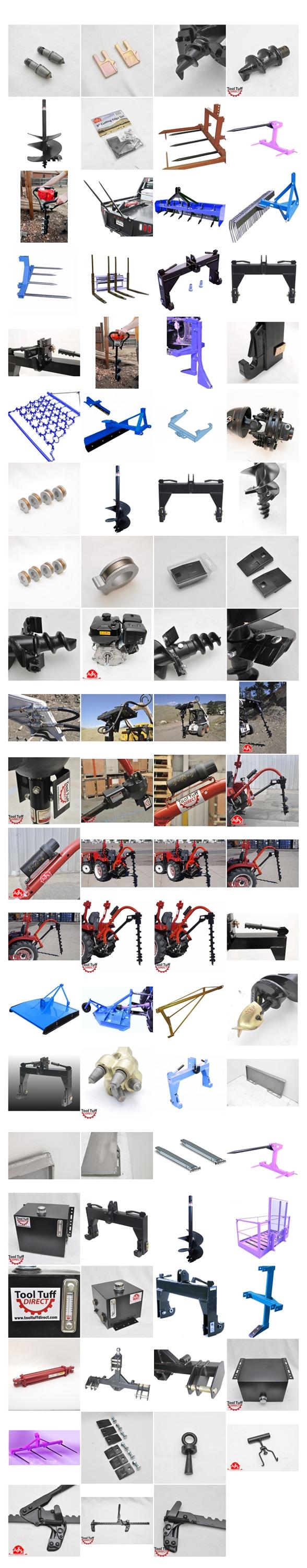

Best China manufacturer & factory Agricultural Machinery Heavy Duty Competitive Low Price Pto Drive Shaft For Agricultural Tractor Spare Parts With high quality best price

Full use has been made of all kinds of advanced techniques and technology to reach excelsior manufacturing.

Overview

Quick Details

- Warranty:

-

1.5 years

- Applicable Industries:

-

Manufacturing Plant

- After Warranty Service:

-

Online support

- Local Service Location:

-

none, Italy

- Showroom Location:

-

ITALY

- Type:

-

Shafts

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- EPG is willing to cooperate sincerely and develop commonly with friends! certificate:

-

CE

- Material:

-

Metal

AT series with tri-lobe tube (triangular) The triangular tube shape is the most used, from lightweight to fairly heavy applications. In the case of applications with high sliding, the R version with Rilsan coating is also available. AL series with two-lobe tubes (lemon).

- Color:

-

The EPG Group of Companies (The EPG Group) manufactures, services and sells a wide range of capital plant equipment to a diverse range of industries. This includes the mining sector, processing, material handling, power generation and oil and gas refineries. To these sectors we provide services such as material handling, geotechnical instrumentation, boiler cleaning technology and engineering consultancy services, amongst others.

Yellow&Black

- Processing of yoke:

-

Forging

- Processing of tube:

-

Cold drawn

- Design:

-

Customized

- Certificate:

-

CE Certificate

Supply Ability

- Supply Ability:

- 20000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Iron crates

- Port

- NINGBO OR SHANGHAI

Online Customization

Product Information

Product Information

PTO Shaft

The power take-off (PTO) is a sophisticated mechanism, allowing implements to draw energy from the engine and transmit it to another application. It works as a mechanical gearbox which can be mounted on the vehicle’s transmission.

The power take-off shaft (PTO shaft) is a critical component, designed and manufactured for continuous heavy-duty use. A good PTO shaft should be strong enough to bear the torsion and shear stress and minimize vibration.

Setforge, the forging subsidiary of Ever-Power Group, manufactures cold extruded PTO shafts for all types of agriculture vehicles. Our PTO shafts offer great dependability and durability during daily use.

EP Group has been internationally recognized as a reliable global supplier. Our state-of-the-art manufacturing process and experienced engineers ensure the top-quality of all Farinia components.

| After Warranty Service | Video technical support |

| Applicable Industries | Manufacturing Plant |

| Local Service Location | Italy |

| Showroom Location | Italy |

| Warranty | 1.5 years |

| Type | Shafts |

| Place of Origin | China |

| China | Zhejiang |

| Brand Name | EPG |

| certificate | CE |

| Material | Metal |

| Color | Yellow&Black |

| Processing of yoke | Forging |

| Processing of tube | Cold drawn |

| Design | Customized |

| Certificate | CE Certificate |

Product Display

Product Display

L series aluminium …

PTO drive shaft Hi …

PTO Drive Line Gen …

CompanyInfo

Company Profile

Ever-Power Group

EPG have high-tech machinery and test equipment. We can produce world class high precision products.

Certifications

Certifications

Shipment & Payment

Our Advantages

A: Your inquiry related to our products or prices will be replied in 24 hours.

B: Protection of your sales area, ideas of design and all your private information.

C: Best quality and competitive price.

……

faq

FAQ

1) How can I place order?

A: You can contact us by email about your order details, or place order on line.

2) How can I pay you?

A: After you confirm our PI, we will request you to pay. T/T (HSBC bank) and Paypal, Western Union are the most usual ways we are using.

……

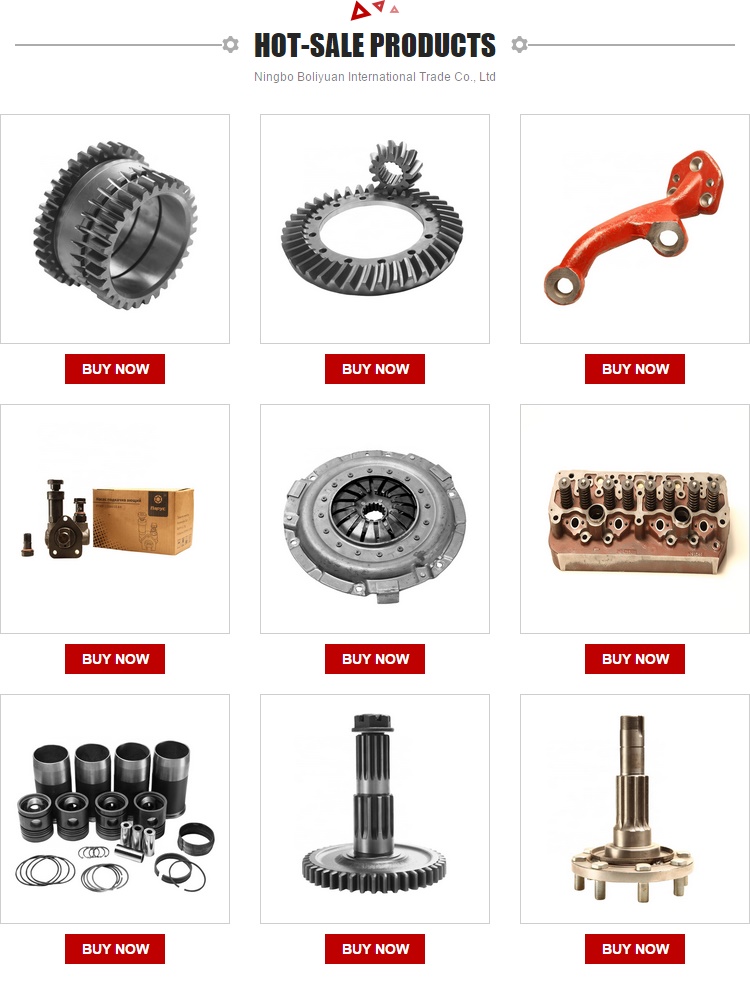

Best China manufacturer & factory factory manufacturer for High quality big gear angular tractor wheel With high quality best price

If you need any information or samples, please contact us and you will have our soon reply.

Worm gears are typically manufactured by hobbing with a hob or cutting tool very similar to the worm that the gear mates with. The worm may be turned, hobbed, milled, or ground. Cat 3 Point Hitch How do I operate the PTO on my tractor? Prior to running the PTO, you will need your tractor to reach the starting RPM (revolutions per minute). Once the starting RPM has been reached you can begin operating the PTO.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Product Keywords:

-

EPG Machinery is located in XiHu Area HangZhou Zhejiang ,China. It is 30km from our factory to HangZhou international airport.

big gear,angular gear,tractor gear wheel

Supply Ability

- Supply Ability:

- 5000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Neutral paper packaging, wooden boxes for outer box or according to customer’s demand.

- Port

- Shanghai Port / Ningbo Port

Online Customization

We Ever-Power Group with 4 branches over 1200 workers is one of the biggest transmission parts and machining items manufacturers in China

Product Description

Product Description:

We specialized in manufacturing automobile gears , motorcycle gears, gearbox, special vehicle (power takeoff, snowmobiles, engineering vehicles) gears, generator accessories, stainless steel ice crusher etc.

|

Material |

1020,1045,20CrMnTi, etc. |

|

Machining Process |

Gear Hobbing , Gear Shaping, Gear Shaving, Gear Grinding |

|

Modules |

1.0, 1.25, 1.5, 1.75, 2.0, 2.25, 2.5….8.0 etc. |

|

Heat Treatment |

Carburizing & Quenching, Carbonitriding |

|

Standard |

DIN, ISO/GB, AGMA, JIS,ISO/TS16949:2009 |

Best China manufacturer & factory Best price MTZ tractor parts helical gear transmission wheel gear 50-2403021 With high quality best price

we supply chromed bar and tubes for hydualic and pheumatic cylinders, pto shaft, agricultural gearboxes etc.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Place of Origin:Zhejiang, Chi”EPG” brand rotocultivator ploughshares in T.S. total lines produced in our factory have been tested and appraised by the Ministry of Agriculture and have obtained the license of popularizing farm machinery promulgated by the Ministry of Agriculture of the People’s Republic of China. na

- Brand Name:

-

OEM

- Product Name:

-

helical gear

- Color:

-

Silvery

- Material:

-

20CrMnTi

- Size:

-

33*33*3.5cm

- weight:

-

9.3kg

- Technics:

-

Shot blasting

- Application:

-

Tractor MTZ

- Sample:

-

Free

- Certification:

-

ISO9001:2008

- OEM:

-

50-2403021

Supply Ability

- Supply Ability:

- 50000 Set/Sets per Day

Packaging & Delivery

- Packaging Details

- 4pc

- Port

- Tianjin xingang port, Lianyungang port. Yiwu port, Shanghai

-

Lead Time

: -

Quantity(Bags) 1 – 500 501 – 1000 >1000 Est. Time(days) 7 15 To be negotiated

Online Customization

| Applicable Industries | Machinery Repair Shops,Farms |

| Use | Tractors |

| Place of Origin | China |

| China | Xinjiang |

| Brand Name | Paruc |

| Product Name | helicTo eliminate contact-pattern inconsistencies, EPT developed an automated centering machine that accurately measures each worm and gear subassembly, as well as the reducer housing and bearing coversClose up of shear pin which will shear in half if the implement is subject to sufficient resistance Shear pin: the shear pin shaft I use for the chipper/shredder. The driven end yoke is actually two pieces with a shear pin or bolt that holds the two pieces as one during operation. Should the equipment encounter a sudden stop the pin will take the shock and “shear off” preventing any driveline damage. . A computer records the data and calculates the thickness and location of shims required to exactly center the gear under the worm shaft and, at the same time, provides the appropriate end 1play for the output tapered-roller bearings. This maximizes operating efficiency and minimizes temperature rise.al gear |

| Color | Silvery |

| Material | 20CrMnTi |

| Size | 33*33*3.5cm |

| weight | 9.3kg |

| Technics | Shot blasting |

| Application | Tractor MTZ |

| Sample | Free |

| Certification | ISO9001:2008 |

| OEM | 50-2403021 |

Transport mode: Free sample is available once you accept the freight collect

Payment term: 30% T/T, L/C at sight

Q1:How your company usually transports goods to your countries?

This problem is mainly determined by the quantity of the goods. If the number of orders is sufficient for a container, it is recommended that containers be shipped by sea or rail; if the number of orders is small, they can be shipped by the shipping company.

Q2:Is your company’s products retailable?

Sorry, we do not accept retail orders. Our order quantity is determined according to the packaging of the goods. For example, if there are 30 cases in one box, then 30 are the lowest order quantity.

Q3:What is the payment method?

If it is a spot, we need to receive the full payment before they can be shipped; if it is an order, then according to the prepaid 30%, the remaining 70% of the payment before the contract to sign the contract.

Best China manufacturer & factory Agricultural Tractor Freewheel Clutch Cardan Pto Drive Shaft With high quality best price

Additionally, all our production procedures are in compliance with ISO9002 standards for a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

- Warranty:

-

1.5 years

- Applicable Industries:

-

Manufacturing Plant

- After Warranty Service:

-

Online support

- Local Service Location:

-

none, Italy

- Showroom Location:

-

ITALY

- Type:

-

Shafts

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- certificate:

-

CE

- Material:

-

Metal

- Color:

-

Yellow&Black

- Processing of yoke:

-

Forging

- Processing of tube:

-

Cold drawn

Are you searching for a PTO water pump or PTO- driven generator? Hundreds of PTO parts from EPG mean you can find PTO shaft parts and accessories for whatever kind of equipment you’re working with. From PTO drive shafts to shield parts, we have dozens of replacement PTO parts. We stock Eurocardan parts as well as Neapco parts because those are names you can trust. Whether you need flex couplers or PTO shaft assemblies, we can help.

- Design:

-

Customized

- Certificate:

-

CE Certificate

Supply Ability

- Supply Ability:

- 20000 Piece/Pieces per Month

Packaging & Delivery

- Packaging Details

- Packing details:Iron pallet&wooden carton&standard export packaging

- Port

- ningbo or shanghai

Online Customization

Product Information

Product Information

PTO Shaft

The power take-off (PTO) is a sophisticated mechanism, allowing implements to draw energy from the engine and transmit it to another application. It works as a mechanical gearbox which can be mounted on the vehicle’s transmission.

The power take-off shaft (PTO shaft) is a critical component, designed and manufactured for continuous heavy-duty use. A good PTO shaft should be strong enough to bear the torsion and shear stress and minimize vibration.

Setforge, the forging subsidiary of Ever-Power Group, manufactures cold extruded PTO shafts for all types of agriculture vehicles. Our PTO shafts offer great dependability and durability during daily use.

EP Group has been internationally recognized as a reliable global supplier. Our state-of-the-art manufacturing process and experienced engineers ensure the top-quality of all Farinia components.

The company covering 88,000 square meters, has advanced equipment and strong technical strength, such as the numerical control machine tools and machining centers, CSeries P Precision Planetary Gearhead Series P high precision inline planetary servo drive will satisfy your most demanding automation applications. The compact, cube design, universal housing with precision bearings and precision honed planetary gearing provides high torque density while offering high positioning performance. Series P offers exact ratios from 3:1 through 40:1 with the highest efficiency and lowest backlash in the industry.AD/CAM system, industrial robot etc.

| After Warranty Service | Video technical support |

| Applicable Industries | Manufacturing Plant |

| Local Service Location | Italy |

| Showroom Location | Italy |

| Warranty | 1.5 years |

| Type | Shafts |

| Place of Origin | China |

| China | Zhejiang |

| Brand Name | EPG |

| certificate | CE |

| Material | Metal |

| Color | Yellow&Black |

| Processing of yoke | Forging |

| Processing of tube | Cold drawn |

| Design | Customized |

| Certificate | CE Certificate |

Product Display

Product Display

L series aluminium …

Skid Steer Mount B …

Agricultural Machi …

CompanyInfo

Company Profile

Ever-Power Group

EPG have high-tech machinery and test equipment. We can produce world class high precision products.

Certifications

Certifications

Shipment & Payment

Our Advantages

A: Your inquiry related to our products or prices will be replied in 24 hours.

B: Protection of your sales area, ideas of design and all your private information.

C: Best quality and competitive price.

……

faq

FAQ

1) How can I place order?

A: You can contact us by email about your order details, or place order on line.

2) How can I pay you?

A: After you confirm our PI, we will request you to pay. T/T (HSBC bank) and Paypal, Western Union are the most usual ways we are using.

……